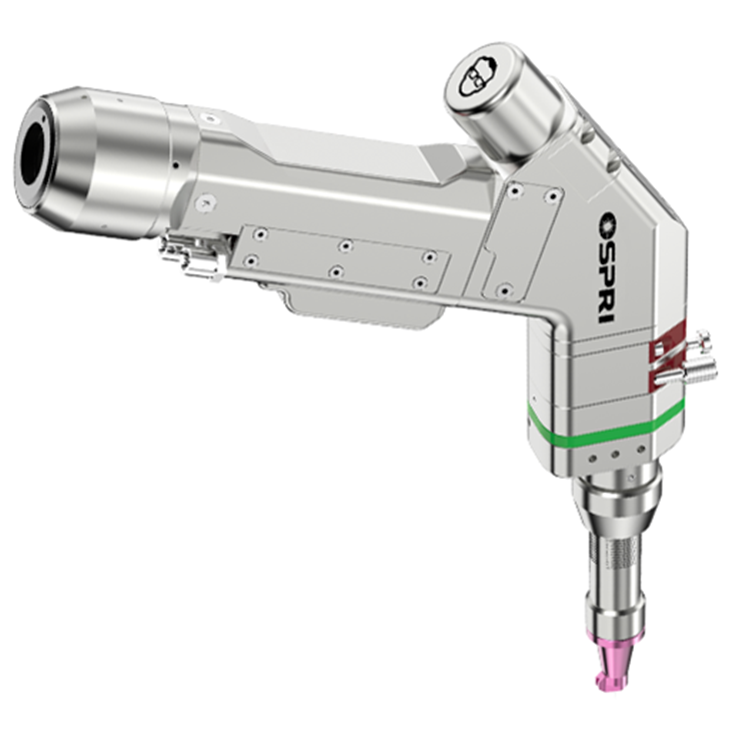

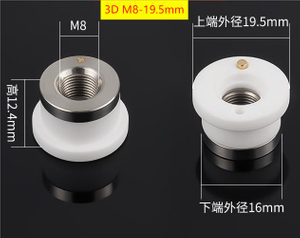

Ceramic Holder/Body Raytools D19.5mm for Raytools 3D cutting head

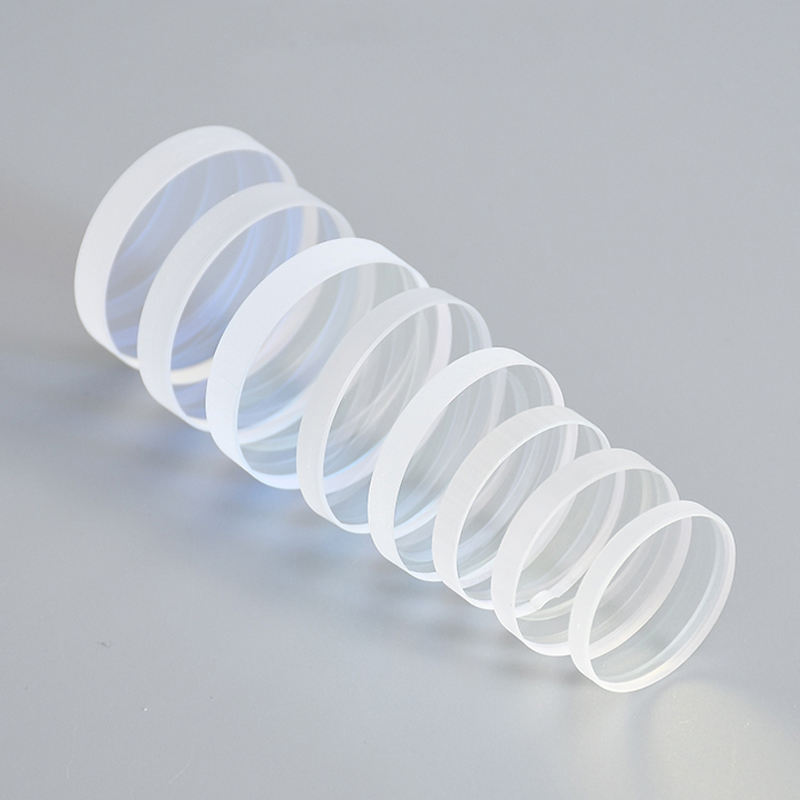

1. Ceramic body

Among them, there are two common raw materials for ceramic body, namely zirconia and alumina. It can be seen from the name that zirconia is more expensive than alumina. The advantages of using zirconia as a ceramic ring are that it has a very small coefficient of thermal expansion (high temperature resistance), a high density (impact resistance and wear resistance) and a high resistivity. Such ceramic body can effectively ensure the insulation between important parts and cutting head, and further reduce the loss of cutting head. Of course, it is reasonable to use alumina to reduce costs, but the replacement cycle of wearing parts will also be shortened.

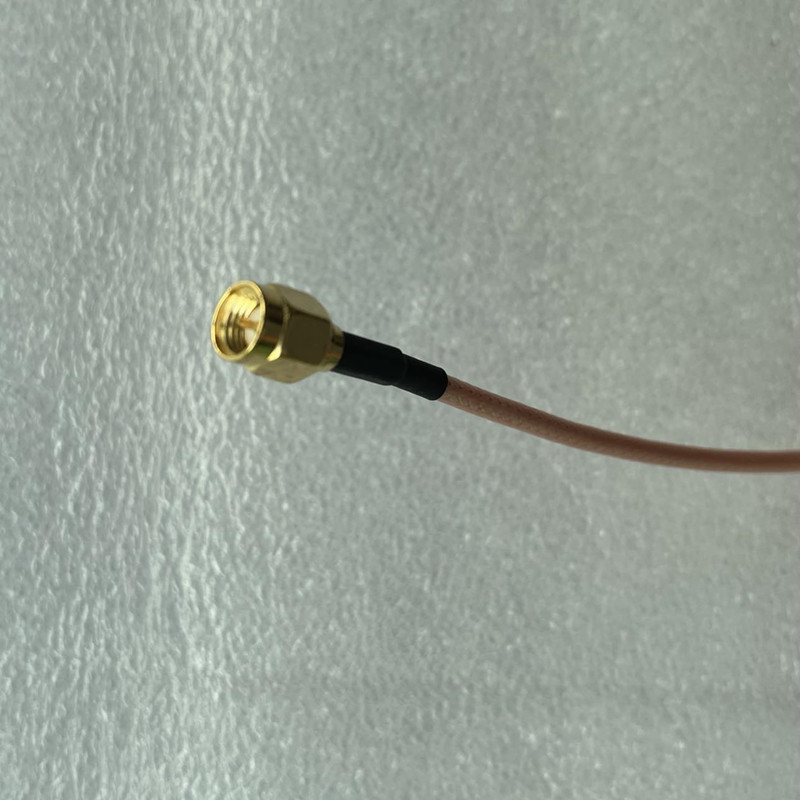

2. Stainless steel sheet.

As we all know, metals generally have the function of transmitting signals. The large area of the stainless steel sheet and the full contact with the nozzle can more accurately and quickly transmit the electrical signal to the copper needle. In order to reduce the deformation of thin stainless steel sheet at high temperature, it also needs many steps. If the treatment is not proper, the stainless steel will be deformed and affect the use.

3. Copper column,

As a medium, the electrical signal collected from the stainless steel sheet is transmitted to the internal transmission line of the laser head to ensure that the controller can adapt to the circumstances. The transmission of electrical signals requires high conductivity, so gold plating is an effective method.

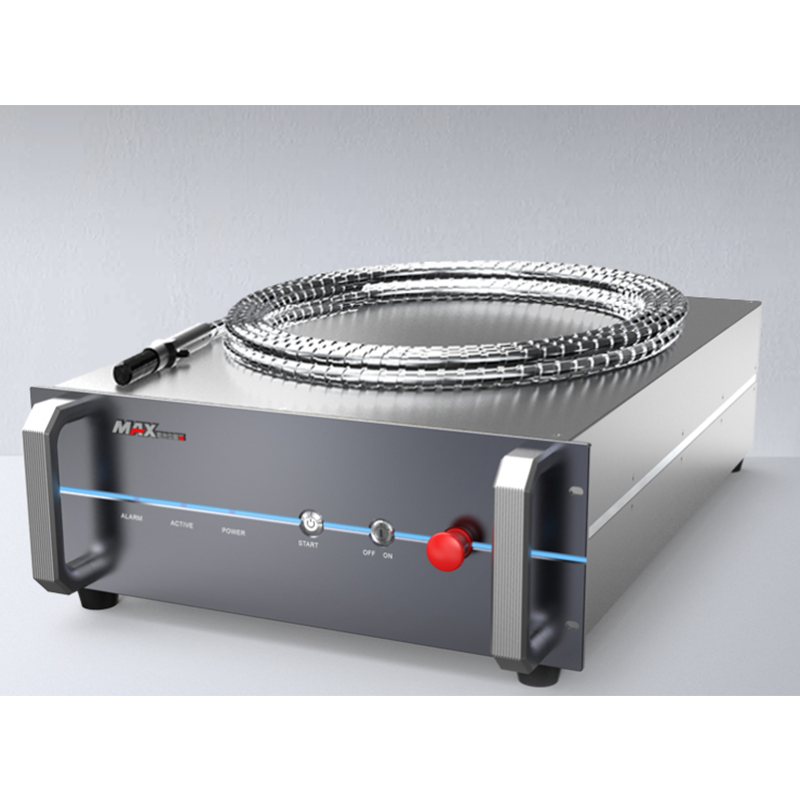

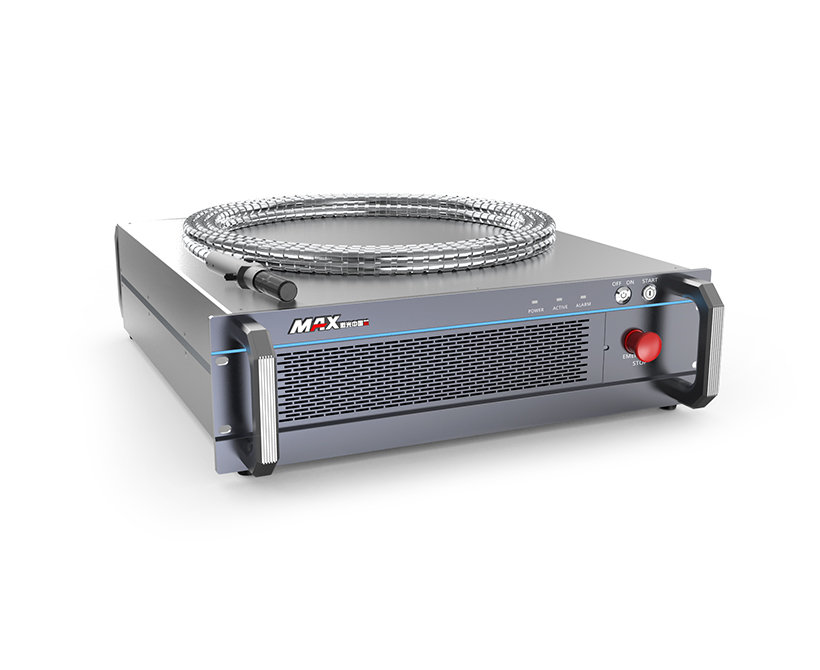

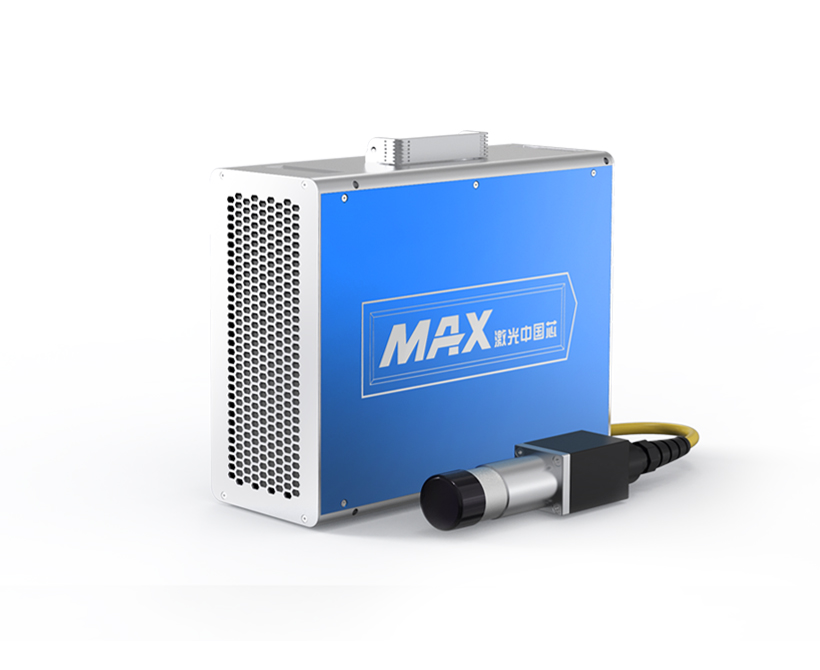

Product Description:

The ceramic ring of laser cutting machine is a high temperature resistant and anti-deformation device,

which is composed of a porcelain body, a copper needle and a stainless steel sheet. The ceramic ring has the

effects of high temperature resistance and anti-deformation, which can ensure stable signal transmission,

and the surface of the ceramic ring has a high surface finish, the airflow can pass smoothly, and the cutting

effect is good.

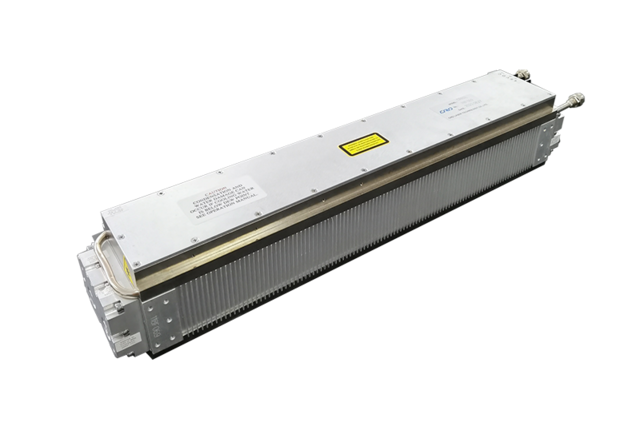

Maintenance guide for cutting head of fiber laser cutting machine

1、 Tips for prolonging the service life of fiber laser cutting head. Relevant technical engineers told Xiaobian that if you want to extend the service life of the cutting head of the fiber laser cutting machine, you can use masking tape to package the upper part of the cutting head after the installation and commissioning of the new laser cutting machine. The purpose of this is to play an effective role in dust prevention and pollution prevention, which is more conducive to the protection of the cutting head of the fiber laser cutting machine.

2、 Every laser cutting and processing master is required to do a good job of dimming correction and confirmation before starting every day. Before starting the machine every day, please check whether the laser is emitted from the nozzle center of the laser cutting head. If there is any deviation, please adjust the light in time and re-align the cutting reference point. If the reference point is correct, the focus of the light path will be accurate, the cutting efficiency will be more efficient, and the cutting quality of the cutting workpiece will be more guaranteed.

3、 Regularly check and clean the ceramic body and ceramic ring of the cutting head of the fiber laser cutting machine. The relevant technical engineers told the editor that the ceramic body or ceramic ring on the cutting head of the fiber laser cutting machine should not be underestimated. The roundness and cleanness of the ceramic body, ceramic ring and nozzle are also important factors to ensure the efficiency and quality of laser cutting. If any foreign matter or dirt is found, use a cotton swab dipped in isopropanol for wiping and cleaning.

4、 Regularly check the relevant protective lens of the cutting head of the fiber laser cutting machine. The optical fiber laser cutting head that can be seen on the market now basically has upper and lower protective lenses. The main function of the upper protective lens is to prevent dust and other foreign matters from falling onto the cutting head focus lens group. The lower protective lens is to prevent cutting debris and other foreign matters from polluting the cutting head. Regularly check whether the protective lens has dirt, patterns or water mist. In case of any of the above conditions, it can be cleaned by wiping with isopropanol. If it is not cleaned by wiping, the upper and lower protective lenses need to be replaced in time.

1. laserhome always put commitment to our clients in the first place, implementing production according to the

highest quality standards.

2. Normally, all the products involved in this catalog have one- year warranty, which is calculated since the dayof the delivery while the packaging keeps completed. The warranty does not cover the period after the

products unwrapped or used, except the laser cutting head.

3. We ensure declared products’ parameters, we will offer free replacement if products quality cannot meet

certain standards.

4. Returned products must be returned with original packaging so that we can trace and track accurately, and we will provide test reports to clients to prove the factors that lead the malfunction. If it is a quality problem, we will offer free replacement; If some product is damaged on the way returning, we won’t replace it for free.

5. Please kindly notify us at the earliest time if your received products have any damage, take photos and record the evidence. Accidental or man- made damage cannot be compensated.

6. We will not compensate for any damage caused by abusing, misusing, improper handling, accidental damage,failure handling, or damage caused by improper installation.

7. We will not replace the products that have been delivered or used, except for those with quality problems.