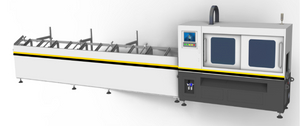

Laser Repair Imported Original Fusion Splicer S185LDF for LDF Splicing High-end Splicing

S185LDF S185PMLDF

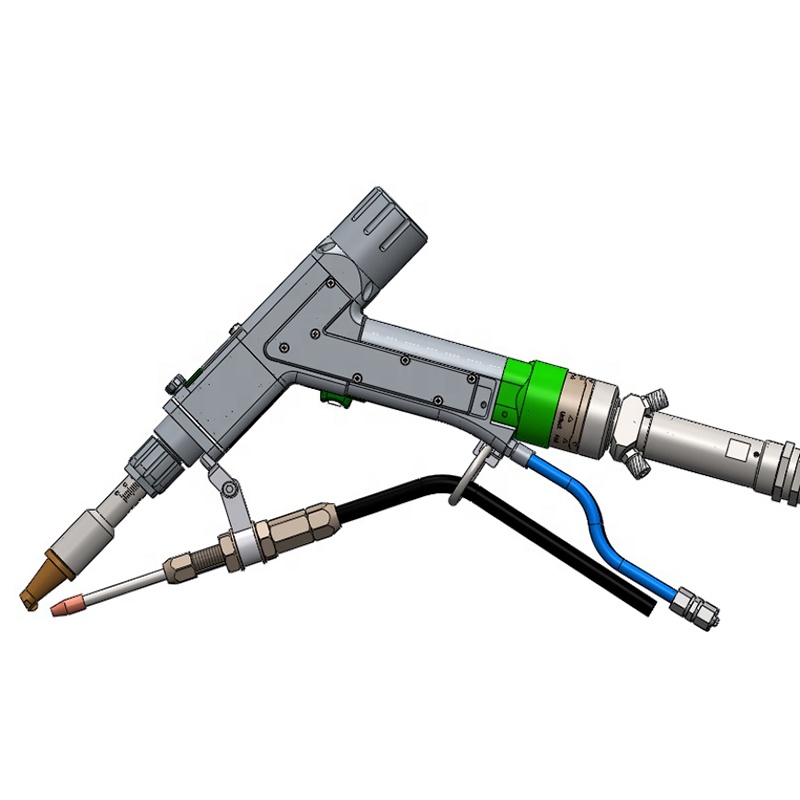

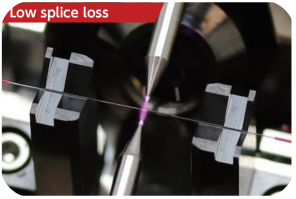

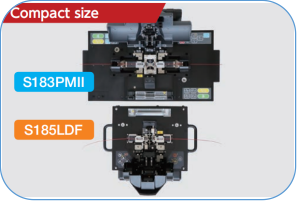

Fusion Splicers for LDF and PMLDF splicing up to 500μm Low splice loss Compact size High capacity built-in battery (Optional) LCD touch panel provides easy operation Fiber clamps land gently to prevent damage to the fiber Remote control by Wi-Fi communication | The FITEL S185LDF / S185PMLDF High�end Fusion

Splicers are designed for splicing up to 500μm cladding fiber with low splice loss. The powerful and compact design has been optimized for the Fiber laser industry. The new fiber alignment mechanism achieves low splice loss. The new design allows for the fiber clamps to land gently to reduce the possibility of damage to fiber. Battery operation and a compact design make transportation easy for the LDF Fusion splicer. |

Features:

Precise alignment with resolution of 0.03μm for fiber axis.

| Fiber clamps land gently to prevent damage to the fiber. |

Footprint is 46% smaller than previous model. | Battery operation and a compact design make transportation easy. |

Easy and intuitive touch panel operation and GUI.

| Automatically adjusts image when LCD

display is flipped.

|

Remote control is available by Wi-Fi. | Releasing the fiber clamp links allow the fiber clamps to be placed without closing the canopy |

Specification

Description | S185LDF | S185PMLDF |

Applicable fibers*1 | SM, MM, DS, NZDS, High-Index, EDF, LDF | SM, MM, DS, NZDS, High-Index, EDF, LDF, PMF |

Cladding diameter | 80 to 500μm |

Coating diameter | 160 to 2000μm (In Fiber holder) 160 to 900μm (Coating clamp splice) | 160 to 1300μm (In Fiber holder) 160 to 900μm (Coating clamp splice) |

Fiber cleave length | 3 to 5mm (Coating clamp splice) 8 to 11mm (Cladding clamp splice) |

Typical splice loss*2 | SM(ITU-T G652): 0.014dB |

Typical extinction ratio*2 |

| PANDA: -36.8dB*3 (Angle offset: 0.6degree) |

Return loss | >60dB |

Typical splice time*4 | 15s (SM by cladding clamp splice) | 15s (SM by cladding clamp splice) 40s (PANDA by cladding clamp splice) |

Tension strength | 1.96 (+0% to +20%) |

Applicable protection sleeve length | 10 to 60mm |

Typical heat time | 35s (S922:40mm sleeve) |

Splice programs | Max.200 |

Heater programs | Max.100 |

Splice data storage | Max. 1000 including 4 images before and after splice |

Fiber image magnification on LCD | 104X, 278X or 556X |

Dimension | 210W x 180D x 150H mm |

Weight (without Battery) | 4.5kg | 4.75kg |

Monitor | 4.3” wide color LCD with touch panel |

Data output | USB ver. 2.0 type A: 1 port USB ver. 2.0 mini B: 1 port |

Battery capacity (Optional)*5 | Typical 60 splice / heat cycles |

Operating temperature | 0 to 40°C |

Storage temperature | -40 to 60°C |

Humidity | 0 to 90% (Non-condensing) |

Power source | AC input 100 to 240V (50/60Hz) |

*1 Fibers should be applied to ITU-T standard. In case of other fibers, depending on the type of fiber, the optimization of splice program may be needed

or the splice result may not be satisfied.

*2 These are references. Depending on the environment and condition, the number vary.

*3 Extinction ratio -36.8dB is measured in the condition that the initial extinction ratio is -40dB and there is the splice with 0.6 degree of rotation offset.

*4 This value is references. Depending on the type of fiber and condition of fiber on splicer, the number can vary.

*5 This value can produce using fully charged brand new battery at room temperature 20 degree C. Depending on the condition of the battery and

operation environment, the number can vary.

Standard package

Standard Package (S185LDF)

Standard Package (S185LDF)

Ordering number form

Optional components

Item | P/N | Quantity |

160μm Coating Fiber Holder | S713S-160 | 1pair |

250μm Coating Fiber Holder | S713S-250 | 1pair |

400μm Coating Fiber Holder | S713S-400 | 1pair |

650μm Coating Fiber Holder | S713S-650 | 1pair |

900μm Coating Fiber Holder | S713S-900 | 1pair |

1300μm Coating Fiber Holder | S713S-1300 | 1pair |

Customized Fiber Holder* 6 | S713S-XXX | 1pair |

Hard Carrying Case | HCC-12 | 1 |

Built-in Battery Pack* 7 | S947B | 1 |

USB Cable | USB-01 | 1 |

Wi-Fi Dongle | WFD-01 | 1 |