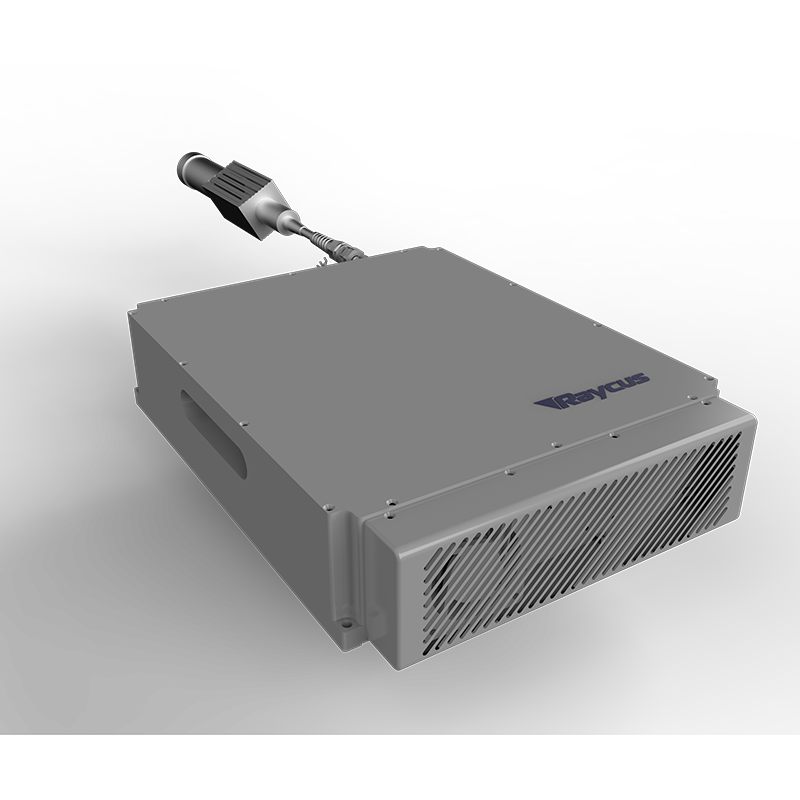

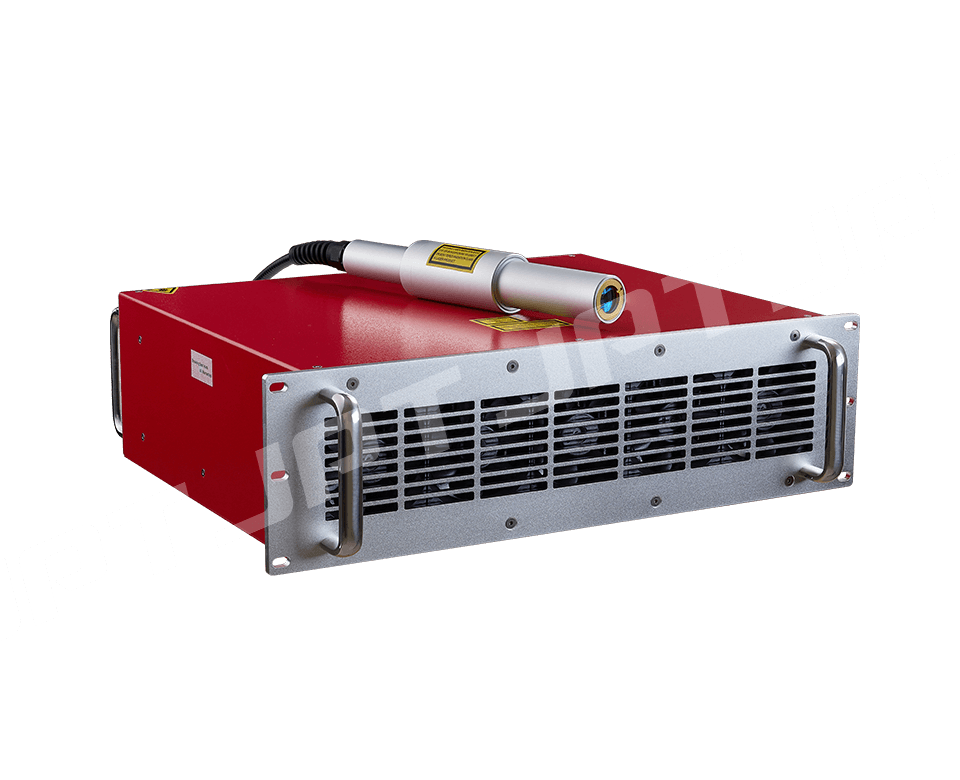

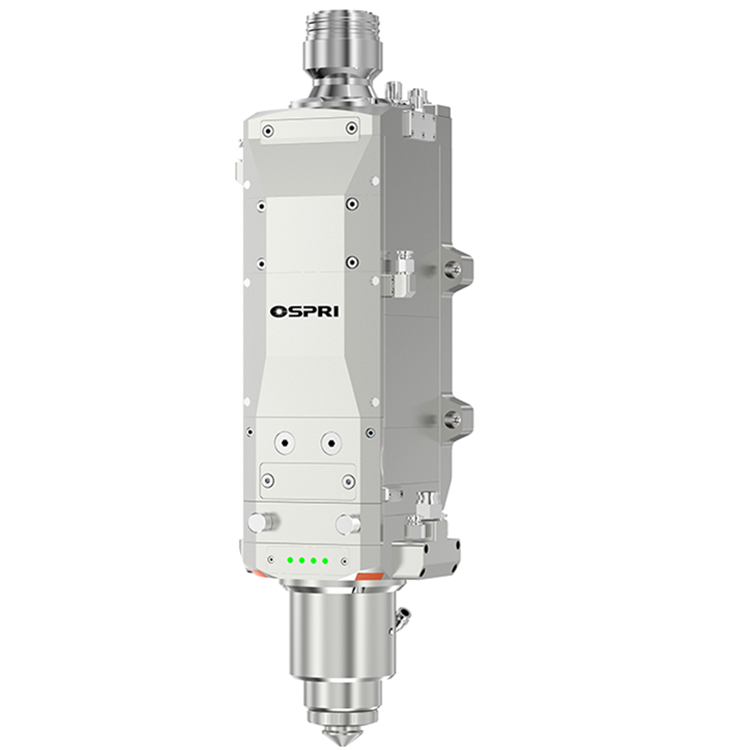

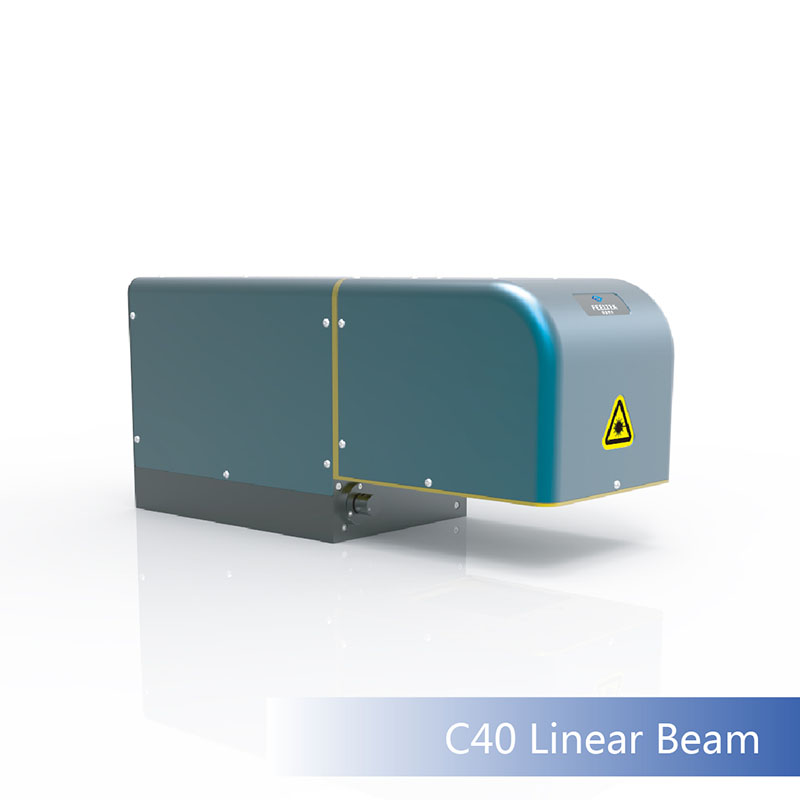

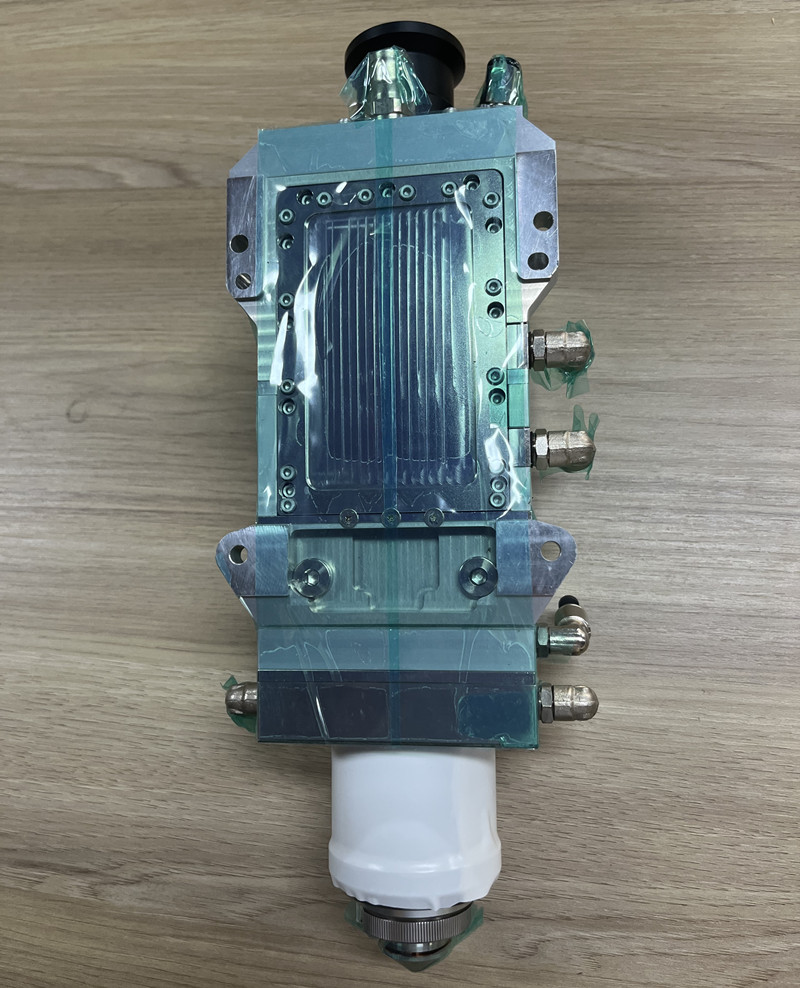

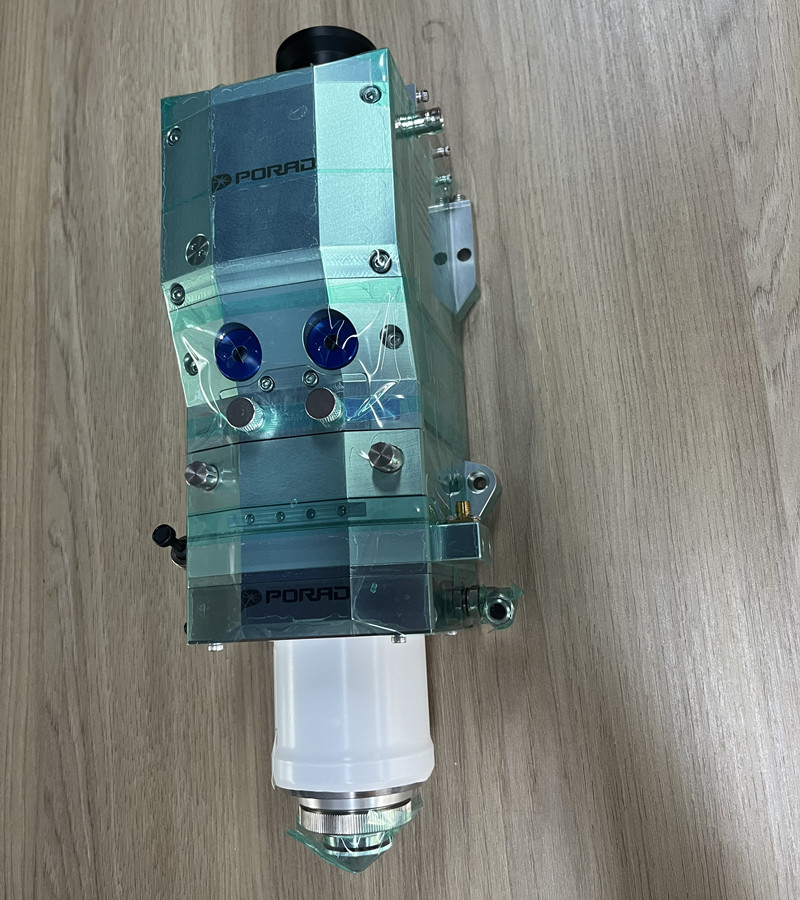

PORAD 20000W PoLeader2.0 Intelligent ultra-high power focusing fiber cutting head for fiber laser cutting machine

Description:

PoLeader2.0 is an intelligent ultra-high power focusing fiber cutting head launched by PORAD in 2020. Compatible with Q+, QD and other optical fiber interfaces, the PoLeader2.0 with a maximum power of 20kW+ will bring a higher quality and faster cutting experience to the laser industry. The newly designed cooling method can bring cooling effect to the optical lens more efficiently and ensure the stability of batch cutting; the newly designed focusing protection replacement method solves the trouble of on-site replacement of focusing protection and the risk of dust fall.

2. Technical parameters:

Applicable fiber power: ≤20000W

Focusing lens focal length: 200mm

Focus adjustment range: +15mm~-30mm

Control mode: analog control

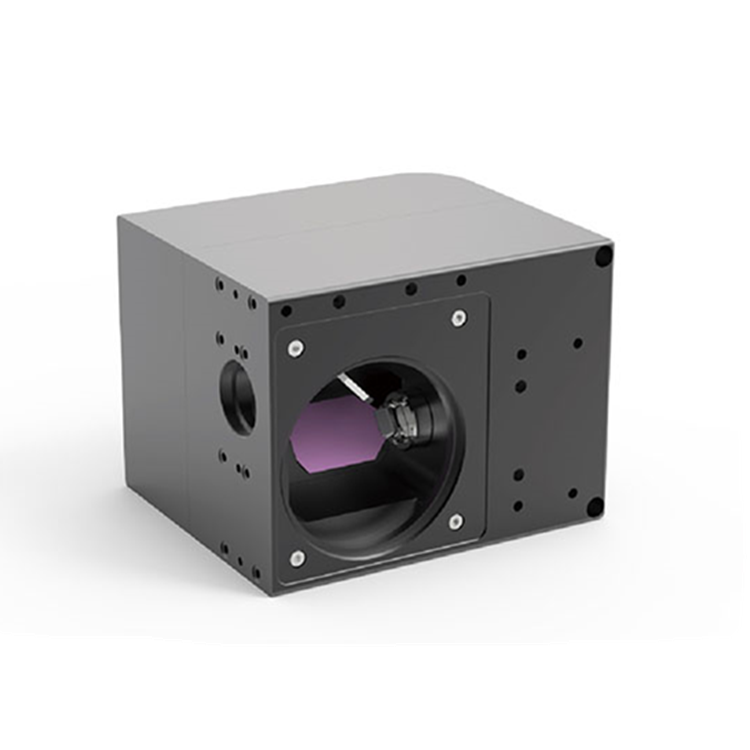

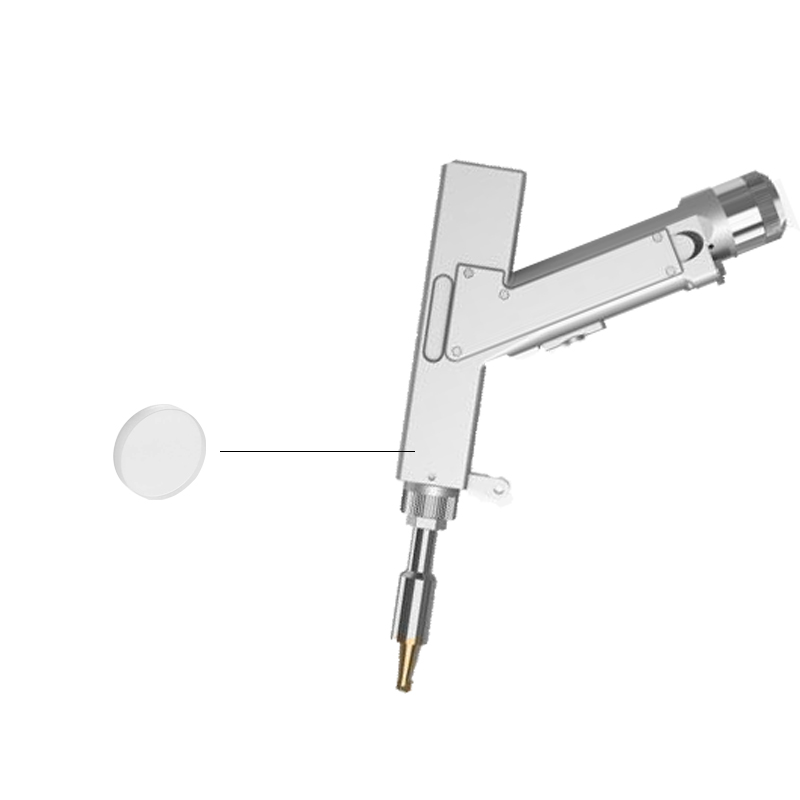

Upper protective mirror specification: ø21.5mm*2mm

Lower protective mirror specification: ø37mm*7mm

Auxiliary gas pressure: ≤2.5MPa

Weight: 6.5~7KG

3. Feature description:

● The new focus protection replacement method provides great convenience for lens replacement.

● Fast Cool cooling technology, which can effectively cool the cutting and cutting plate surface, and solve the problem of poor cutting quality caused by high temperature of cutting materials

● The whole body water cooling method is adopted to cool the optical lens more efficiently; it ensures the stability of batch cutting of plates.

● The monitoring data can be read on the mobile terminal through the wireless network

● Designed a new and effective cutting air circuit, which solved the cutting direction problem caused by the influence of the air circuit when cutting the plate, and ensured the consistency of the effect in all directions of the finished product

The maximum cutting thickness of the 20000w laser cutting machine can reach 90 mm, and the ultra-long thick plate can be cut to 12 meters.

The efficiency of 20000w laser cutting machine;

8mm, 20mm, 30mm carbon steel is also machined. Compared with 12000w, the efficiency of 20000w can be increased by 60%. The cutting quality is more stable, the cross section is better, and the thickness of the bright side is increased to 40 mm.

The speed of 20000w laser cutting machine.

8mm, 20mm, 30mm carbon steel processing speed comparison.

15-16 m/min when cutting 8mm carbon steel.

1.5-2.5 m/min when cutting 20mm carbon steel.

1.1-1.2 m/min when cutting 30mm carbon steel.

3 times the speed, double the profit, and steadily increase the revenue;

The company that purchased the 20000W laser cutting machine highly praised it: it has been used stably for half a year, and the equipment has been working 24 hours a day since its installation, which is more than 3 times faster than 12000W. Especially when cutting 20, 25, and 30mm carbon steel plates, the efficiency is higher than 12KW 50%-60%, the maximum efficiency can be increased to 70%. Efficient and accurate, greatly increase the output, reduce the operating cost, and greatly improve the processing efficiency.

performance advantage.

Automatic lubrication system:

The automatic lubrication system regularly and quantitatively provides lubricating oil to the equipment to ensure the high-speed operation of the equipment, and has the functions of abnormal alarm and liquid level alarm. The system greatly improves the cutting accuracy and effectively prolongs the service life of the transmission mechanism.

Intelligent alarm system:

Intelligent stroke protection, automatic monitoring of the working range of components, installation of international machine tool standard limit springs, built-in laser cutting head capacitance height adjustment function, anti-collision shutdown, improve equipment safety performance and life safety protection, reduce accidents, and improve cutting efficiency.

Security system:

It has an automatic alarm function for abnormal equipment working status, and pushes it to the operation interface through the control center, which improves the efficiency of equipment abnormal troubleshooting, reduces potential safety hazards, and reduces maintenance costs.

What is laser cutting head?

Can a laser cut a human?

How much does a laser metal cutter cost?

How much does a laser cutter charge per hour?