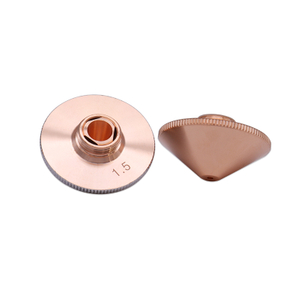

Butterfly Fiber Laser Cutting Nozzle for Laser equipment spare parts Single/Double Laser Cutting parts

Product Description:

| Model | Butterfly nozzle |

| Caliber(mm) | 1.0 1.2 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 |

| Material | imported copper with chromeplated

|

The copper has good electrical and thermal conductivity, and the nozzle made by it can transmit high-quality electrical signals and ensure stable cutting. However, the processing of red copper is difficult, and the scrap rate of finished products is high, so the cost is also high. Many nozzles on the market are actually made of red copper because of their ease of processing. The conductivity of red copper is worse than that of red copper. Cutting machines using copper nozzles often stop for no reason or hit the working surface due to unstable signals and no signals.

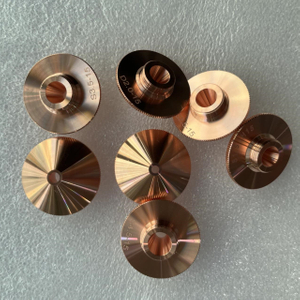

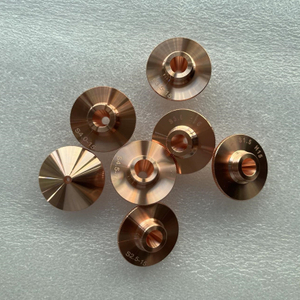

Concentricity is an important criterion for measuring the quality of nozzle processing. It not only affects the efficiency of the adjustment machine, but if the concentricity exceeds the standard, the laser can hit the inner wall of the nozzle and cannot be used. Excellent nozzle concentricity is 0.02mm or less for single layer and 0.03mm or less for double layer. It can be measured using the second element. The roundness of the nozzle directly affects the cutting quality. The roundness of our nozzle reaches 0.005mm. Even for precision cutting, we can meet your requirements.

▷ Butterfly nozzle is made of quality copper material to ensure not the stable signal transmission, but also the fast heat dissipation to prolong service life. The production process of the nozzles is strictly in accordance with manufacturing technique.

The surface is bright and clean, by special passivation treatment, to reduce fly flag adhesion and cutting craters .

We focus on design, quality and customer service

1.Design:Our designers have established a close cooperative relationship with our customers, and have an in-depth understanding of the use environment and actual requirements of the nozzle to ensure product quality from the source.

2.Quality Control:The company has a sound quality control system. From raw material supply, processing management, finished product surface treatment control and pre-shipment inspection, we ensure that all links are controlled and traceable.

3.Customer Service:Customer needs are our driving force. Before the sale, we assist customers to choose the right products. During the use process, we guide customers to use the products correctly. We can use the network to improve video guidance.

①Basing on high-quality copper, high sensitivity, solid and durable

②Precision machining, fully automatic imported machinery, computer-controlled primary machining and molding, high accuracy, smooth inner wall

③A complete range, suitable for laser cutting machines of various brands in the world, with complete specifications.

Features:

1. Single layer nozzles use Nitrogen gas and Air as auxiliary gases to cut stainless steel sheets, aluminum sheets and copper sheets etc.

2. Double layer nozzles use oxygen gas as auxiliary gases to cut metal sheets like carbon steel.

3. High quality nozzle is very important to the cutting quality.

4. The nozzle is made of quality copper material to ensure not the stable signal transmission, but also the fast heat dissipation to prolong service life. The production process of the nozzles is strictly in accordance with manufacturing technique. The surface is bright and clean, by special passivation treatment, to reduce fly flag adhesion and cutting craters .