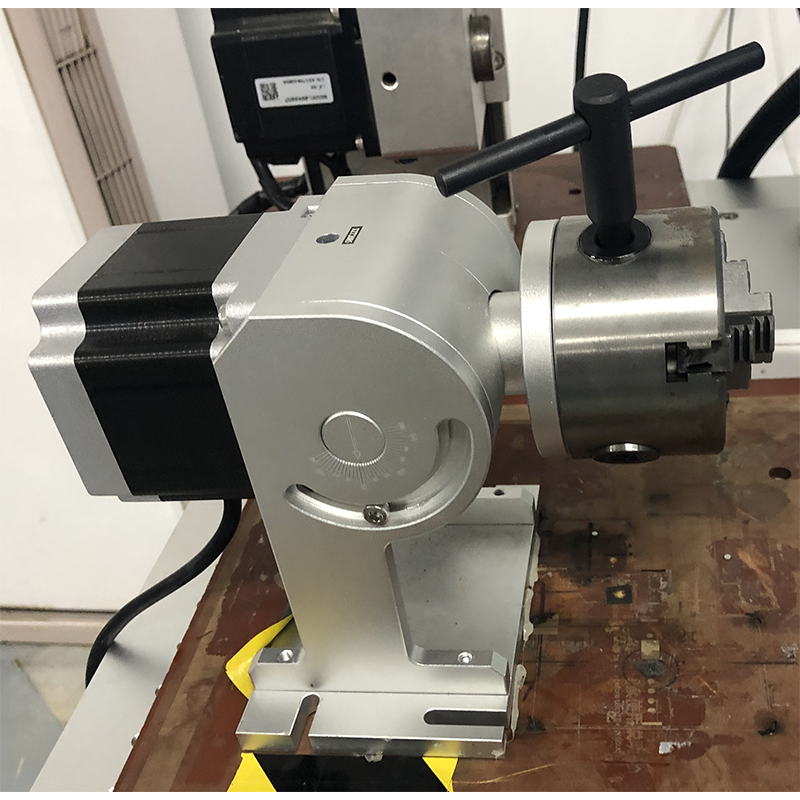

1. Welding LOOP safety protectionThe device is equipped with a safety clip to avoid accidental light emission after lifting the gun.

2. Light warning protectionThere are obvious light indicators on the welding torch and equipment, and the warning is clearly known.

3. Barometric protectionThe equipment is equipped with air pressure protection, and the light is allowed to emit light when the external gas connection is normal.

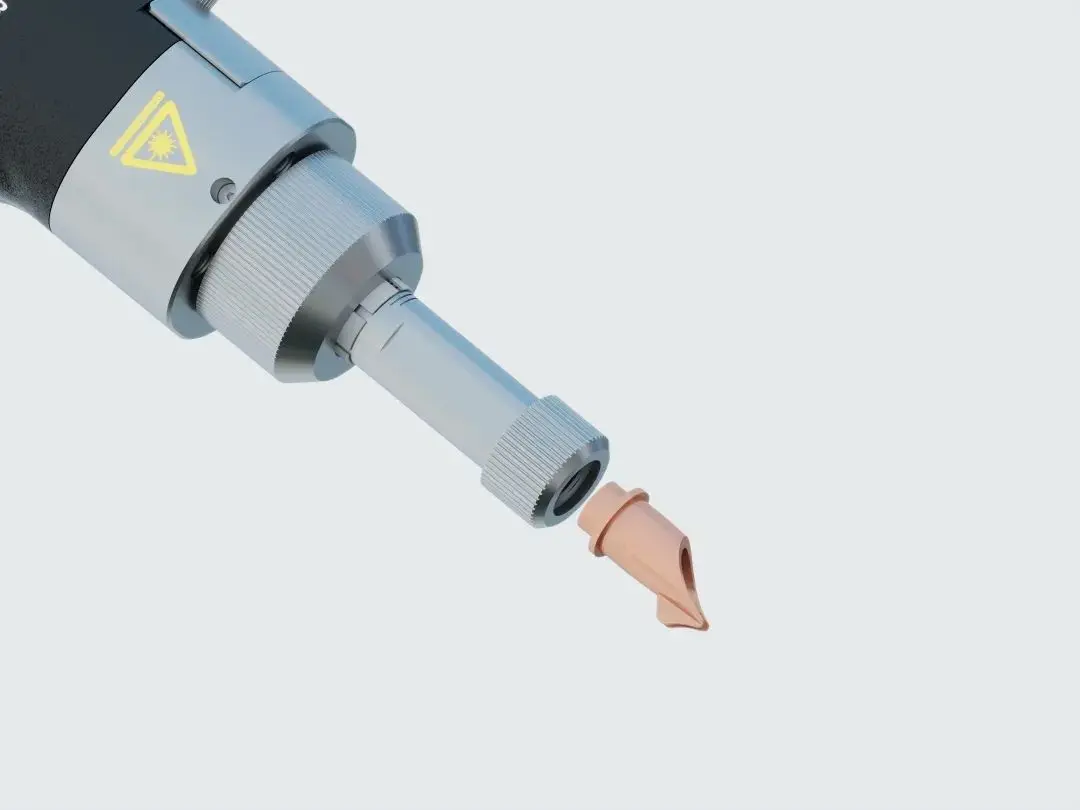

4. Torch temperature protectionThe welding torch is designed to effectively avoid heat and prevent personal injury caused by high temperature.

5. Welding torch button mistakenly touching protectionThe design of the protective shell of the welding torch button prevents the welding torch from mistaking light due to misplacement.

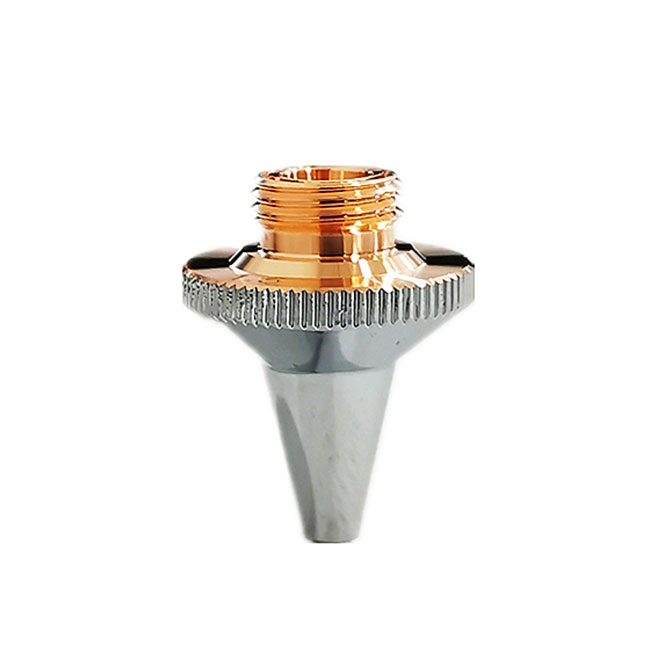

6. Protective lens protectionEquipped with protective lens installation detection function, allowing light to be emitted when the protective lens is installed.

7. External interlocking protectionEquipped with an external safety interlock interface, which can be connected to external emergency stop, safety pedal and other devices. Convenient for factory and production lines safety control.

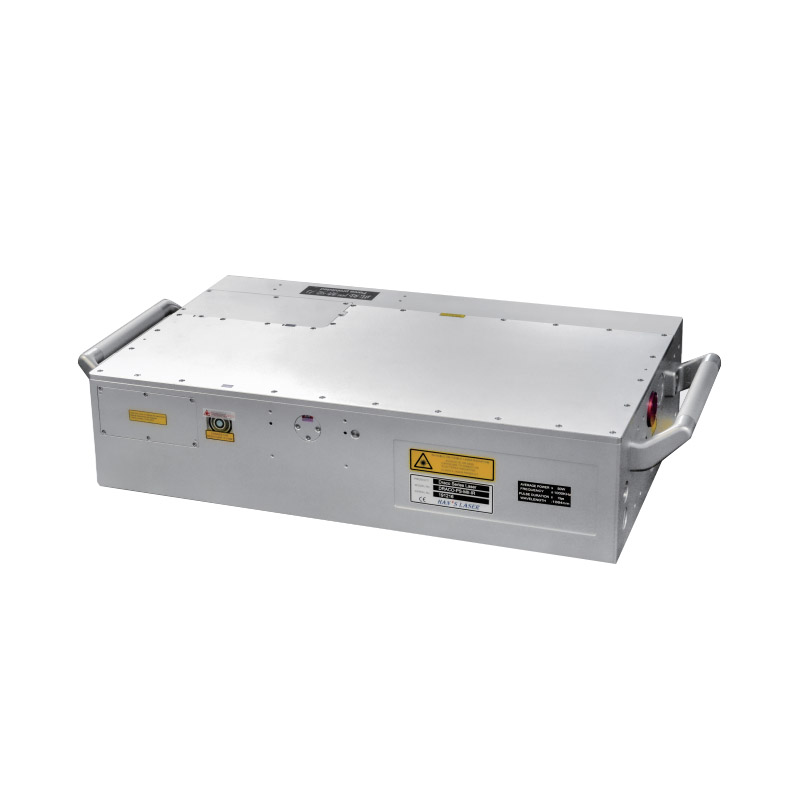

8. Emergency switchAn emergency switch is set on the top of the equipment, which is convenient to stop the equipment immediately when an accident occurs.