1500W Laser handheld high quality automatic fiber laser welding machine for stainless steel iron aluminum copper brass

Handheld laser welding

Machine overview:

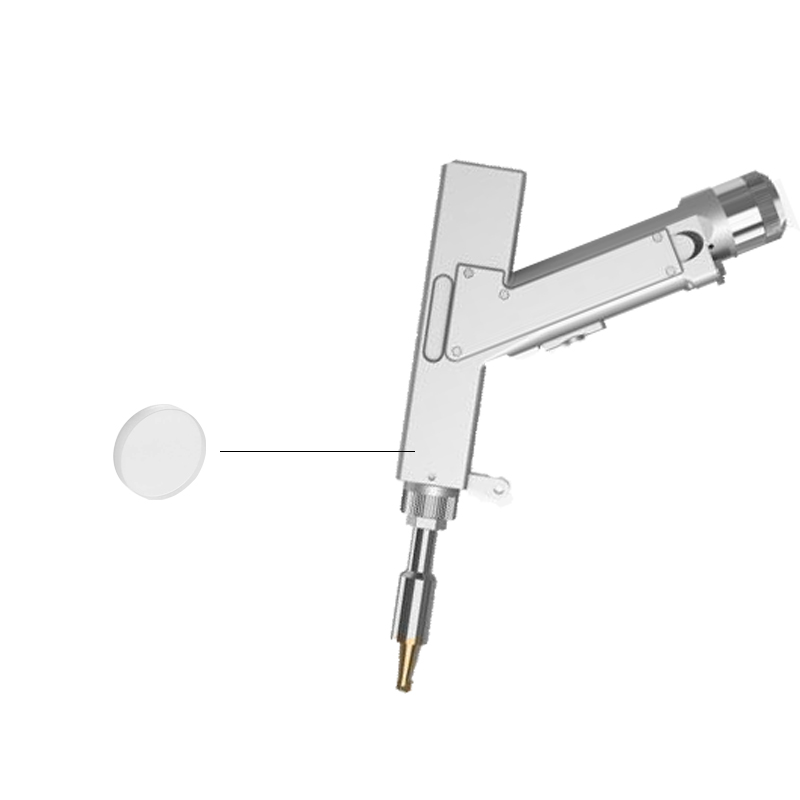

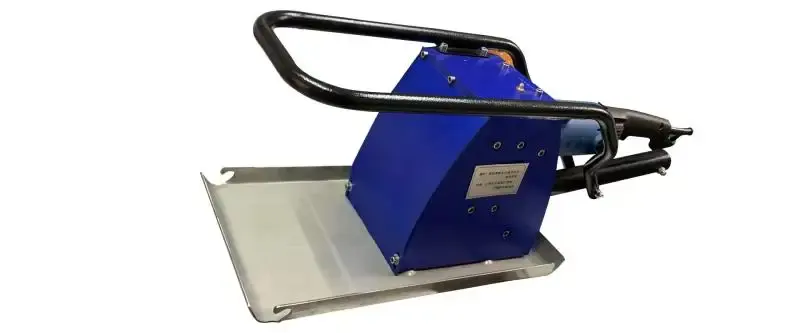

Handheld welding gun

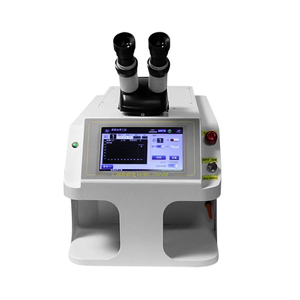

Power on and off emergency stop button

touch screen control surface

Universal wheel with brake

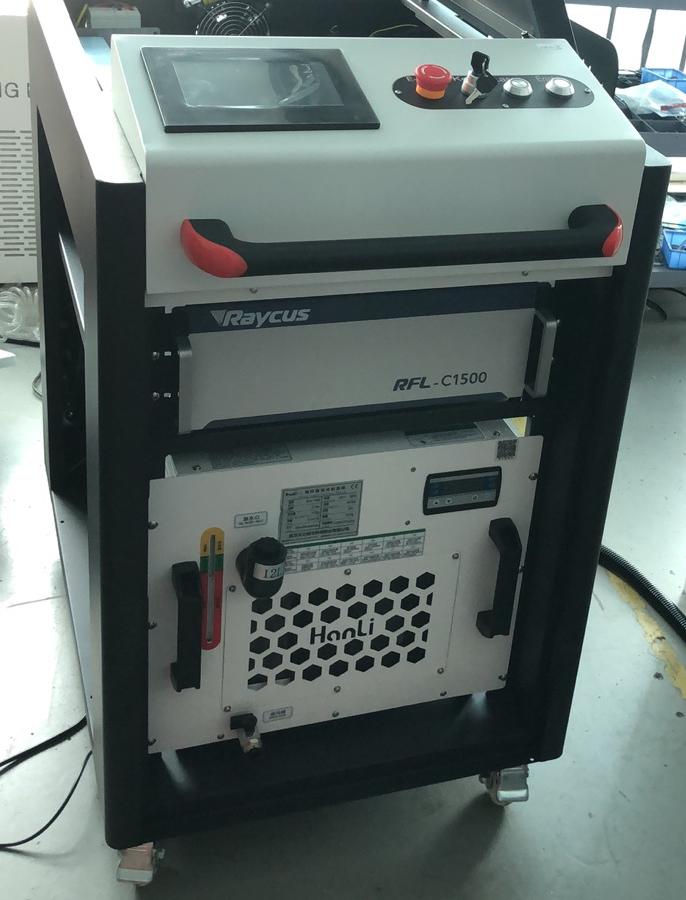

Laser (in the cabinet)

Chiller (in the cabinet)

Matching wire feeder

Welding wire in box

Equipment principle overview:

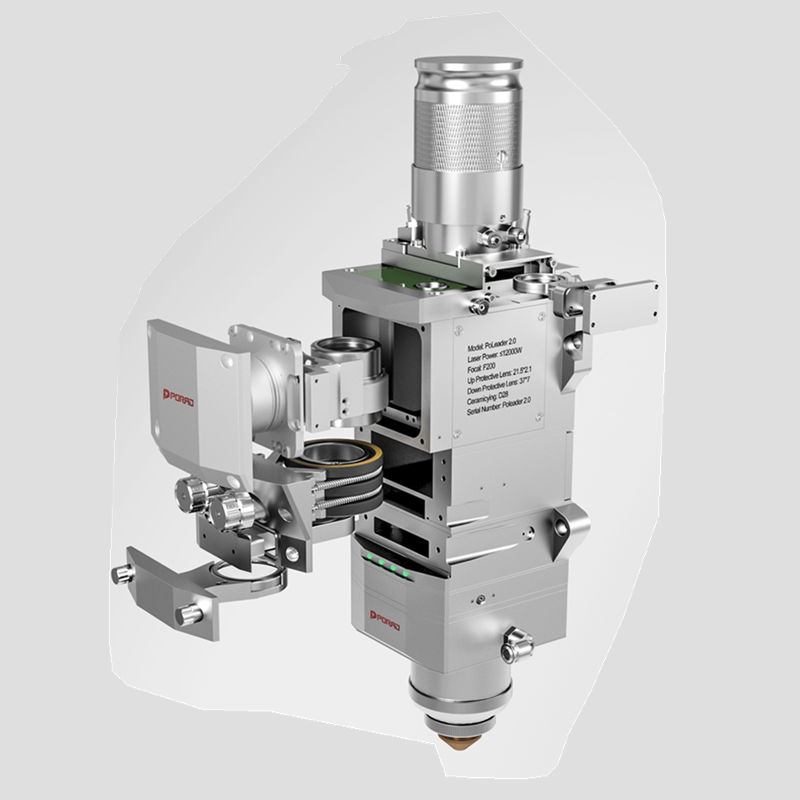

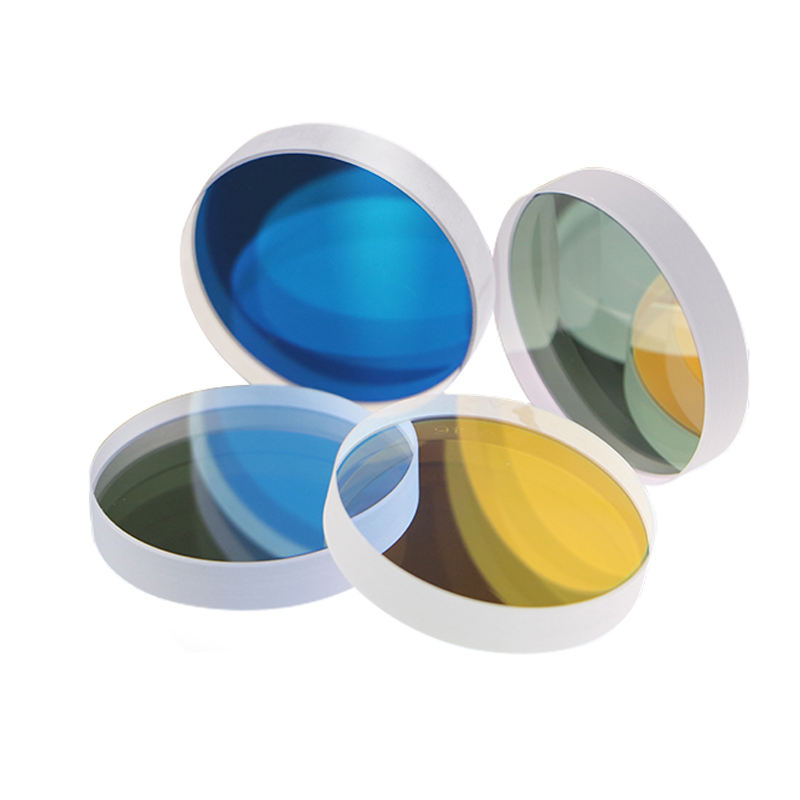

The laser light of the laser is transmitted from the optical fiber line to the hand-held laser welding gun and then focused on the surface of the welding object. After being absorbed by the carrier, it is converted into thermal energy to melt the material or the welding wire to achieve the melting effect. The high-quality weld bead is formed by auxiliary inert gas protection, so that the two The objects are firmly welded together.

(The water of the chiller flows to the laser and the hand-held welding head to cool down and maintain a constant temperature, thus protecting important components.)

Features & Applications

Fast | Performance better | | Free tretment| precision & Eco-friendly

Suitable for welding between titanium, metal, zinc, steel, copper, aluminum, chromium, niobium, metal, gold, and can also be used for welding between different metalsr 。

Applications:

Industry application and sample display

It is suitable for complex and irregular welding process industries such as kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel home furnishing, lighting and molds, advertising words and other industries. Such as various specifications of stainless steel, stainless steel color plate, iron sheet, pure iron, pure aluminum, aluminum alloy, etc., support fillet welding, vertical welding, tailor welding, stitch welding and other welding methods, the welding interface is firm, the welding seam is consistent, Neat and beautiful, not deformed.

Welding Principle:

Laser welding VS the argon arc welding:

Welding samples comparison

Laser welding technical parameters (For reference only):

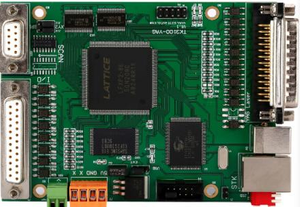

Main components technical parameters:

Note:

Usually, the welding wire is larger than the welding seam, such as the welding seam 1mm, the welding wire should be equal to or greater than 1mm

The diameter of the current welding wire is between 0.8 and 1.6, the minimum welding wire is 0.8, and the thickest is 1.6. If the welding seam exceeds 2mm and the material thickness is more than 2mm, you can try to use "surfacing", that is, repeat adding welding wire to increase the height. (Currently more than 1.6mm weld, it is recommended to confirm with the company's professional and technical personnel)

The aluminum wire is recommended to be matched with the wire of the 5 series or above (such as 5356, etc.), and the diameter of the aluminum welding wire is recommended to be more than 1.2mm.

Machine inner look:

Installation and debugging:

The company is responsible for guiding the installation and commissioning of the equipment. According to the contract, after receiving the payment, the company will arrange delivery. Before delivery, the company will communicate with your company in advance to prepare for the corresponding power supply, electrical, site requirements and other preparations.

Our equipment has sturdy packaging suitable for long-distance transportation and multiple handling, loading and unloading, so as to avoid damage to the boxes during transportation, and we have protective measures such as moisture-proof, mildew-proof and rust-proof according to the characteristics of the equipment to ensure that the equipment is not damaged. In case of safe arrival location.

6.2 Main installation environment

Workshop temperature: 5-38 ℃, when it is lower than 5 ℃, add antifreeze and turn on the laser when the temperature reaches 15 ℃ or more after starting the chiller

Humidity: 30%-85% without condensation

Three no: no dust, no oil fume, no corrosive gas, need to use isolation voltage stabilizer and good grounding

6.3 Pre-sale, in-sale and after-sale service

(1) Pre-sales service

Before signing the contract, the company can provide customers with product samples and technical and price consultation and answers free of charge.

(2) On-sale service

If there are any technical problems during the installation of the product, you can contact the local regional manager or after-sales technicians at any time. If you need on-site technical support, you can communicate with the local sales manager and arrange for the company to coordinate.

(3) After-sales service

Customer service response time is within 24 hours within the warranty coverage of the contract term,