We committed to providing professional laser manufacturing and processing solutions for the industrial manufacturing field. It develops, manufactures and sells the core components of laser processing control systems. With its excellent product quality and perfect after-sales service, it has won customers. recognition and trust, and established long-term and stable cooperative relations with many leading enterprises in the domestic laser field. Our company has a professional R&D team engaged in high-speed optical scanning galvanometer, laser and galvanometer software and hardware control systems, and has the R&D strength of continuous innovation and breakthrough. The company's self-developed full-digital scanning galvanometer series, full-closed-loop laser welding control system (TK6100 series), high-speed spectroscopic control system and other products enjoy a high reputation in the field of laser applications.

Welding control system:

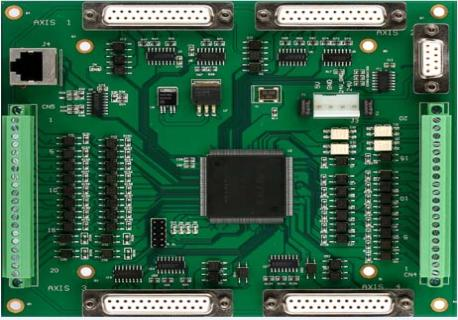

1. Laser and galvanometer control system TK3100 :

Product Details:

a. Support digital galvanometer, interface XY2-100 or SPI can be equipped;

b. Support offline work, can store up to 16 offline documents, and a maximum of 16M for a single document; Rich engineering supporting I/O resources, providing up to 10 channels of input and 8 channels of output;

c. With motor expansion axis interface, it can directly drive the motion control card, and can also realize platform/axis control in offline conditions;

d. The USB interface is used to connect with the PC, the structure is relatively simple, and the wiring is convenient.

Product Details:

a. Support digital galvanometer, interface XY2-100 or SPI can be equipped; support offline work, can store up to 16 offline documents, and a single document can be up to 16M;

b. Rich engineering supporting I/O resources, providing up to 15 channels of input and 15 channels of output;

c. With motor expansion axis interface, it can directly drive the motion control card, and it can also realize platform/axis control when offline; with 1 CCD compensation serial port, it can directly interact with the CCD control software (optional);

d. The USB interface is used to connect with the PC, the structure is relatively simple, and the wiring is convenient.

Welding Control System Description:

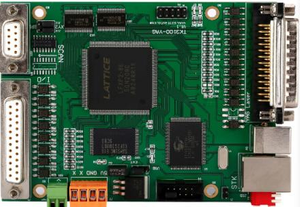

STK motion control card:

Product Details:

In some welding application scenarios, users need to control the movement of some axes, such as table translation, rotation, and so on, while using galvanometer welding. However, since the galvanometer welding system and the motion control card are generally provided by different manufacturers, they need to be operated with their own software, and the software also needs to interact with each other, which generally requires secondary development, which increases the difficulty of the system design.

The STK card function description is as follows:

Number of controllable axes: 1~4, point movement;

Control mode: closed-loop control;

Each axis encoder feedback channel;

Home, positive and negative limit for each axis;

Handwheel pulse follow function for each axis;

Provide 4 general-purpose digital inputs and 7 general-purpose digital outputs;

2. High Speed Optical splitter card

Product Details:

The galvanometer laser transfer card is a standard interface board between the galvanometer control unit and the laser. It realizes one laser with multiple sets of vibration working systems, which can effectively save space for customers, laser energy consumption, and improve economic benefits. The transfer card is divided into standard version and high-speed splitting version. The standard version supports time splitting and energy splitting modes, and the high-speed splitting version supports high-speed splitting. The hardware and external wiring of the two are the same, but the logic functions are different. In the actual application process, the transfer card is generally placed in the laser, and then leads out multiple ports to the laser panel. Multiple sets of galvanometer working systems can be connected to only one or more sets to work at the same time according to production requirements, and the use is flexible.

High-speed spectroscopic motor:

Product Details:

The high-speed spectroscopic system adopts a closed-loop control strategy in each link to ensure the stability and reliability of the system.

The spectral frequency of the high-speed spectroscopic system can reach up to 100Hz, which can double the efficiency of the YAG laser and nearly double the efficiency of the fiber laser.

The high-speed spectroscopic system adopts a digital closed-loop motor, and its repetition accuracy is less than 25urad, which can realize high-precision control.

The high-speed spectroscopic system can provide the original one laser to multiple workbenches for simultaneous use, and each channel is independent of each other and does not affect each other.

High-speed splitting module:

Product Details:

1. Unique modular design, integrating power supply, control and optical path, simple but not simple;

2. High-speed splitting, 2-4 channels are optional, to meet various needs of customers;

3. High-speed spectroscopic motor closed-loop algorithm with independent intellectual property rights to ensure the stability of each optical path under high-speed switching;

4. Customers can flexibly configure YAG laser or QCW quasi-continuous laser to achieve high-speed spectroscopic requirements;

Key technical indicators:

1. The spectral frequency can be up to 100HZ;

2. Spectroscopic accuracy 20um

High-Performance Scanning Galvo:

1. Product details of digital grating galvanometer:

Function description and advantages:

All-digital closed-loop galvanometer, which can sample the swinging position of the galvanometer from time to time to reduce defective products in laser processing; digital feedback, strong anti-interference ability, and repeat positioning accuracy is much higher than that of analog feedback system;

Closed-loop galvanometer control principle

1) The control system sends motion commands to move the galvanometer to the processing point;

2) The galvanometer feeds back the real-time position command, and the control system waits for the galvanometer to be in place;

3) After the galvanometer is in place, check whether the laser can accept the light output command;

4) After the laser is allowed to emit light, the control system sends a light-emitting command;

2. Product details of digital photoelectric galvanometer:

Tongke C series galvanometers are based on analog driver technology and use high-precision photoelectric sensors as feedback devices, with excellent dynamic performance and compact structure.

This series of galvanometers provides a variety of clear apertures, and can be equipped with lenses of different wavelengths and different power levels, suitable for a variety of F-theta lenses with different focal length ranges, to meet various application scenarios, such as ordinary laser marking, flying marking marking, optical scanning, drilling, micromachining, medical, semiconductor and electronic industry marking, etc.

Waveform editing module:

Product Auspiciousness:

Since the control interface of the IPG fiber laser is inconsistent with the control interface of the mainstream welding machine lasers on the market, it is very inconvenient for users to use the laser. To this end, we have developed the IPG laser control board and its supporting software, which converts the control interface of the IPG laser into a general control interface, and has functions such as waveform storage.

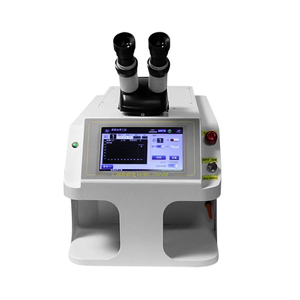

QCW fiber laser high-speed spectroscopic laser and galvo scan head welding control system:

Mobile phone connector laser welding system

USB interface laser welding system

Pressure sensor precision laser welding system

Mobile phone zoom motor precision laser welding system

Mobile phone hardware shell case precision laser welding system

Glasses Frame Precision Laser Welding

Glasses nose bridge frame precision laser welding

titanium alloy material glasses frame precision laser welding

Stainless steel material glasses frame precision laser welding

new energy industry laser welding :

Capacitor Electrode Laser Welding system

Battery case Laser Welding system

Battery cap nickel sheet and tab laser welding system

Battery bus laser welding system

Other applications:

Electronic components precision laser welding system

Computer hard disk internal parts laser welding system

Digital Product Laser Welding System