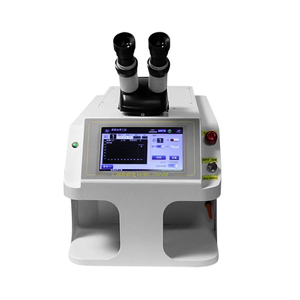

Laser Welding Machine 2000w Competitive Price Laser Welding Machine Fiber Welding Laser Machine

Handheld laser welding

Machine overview:

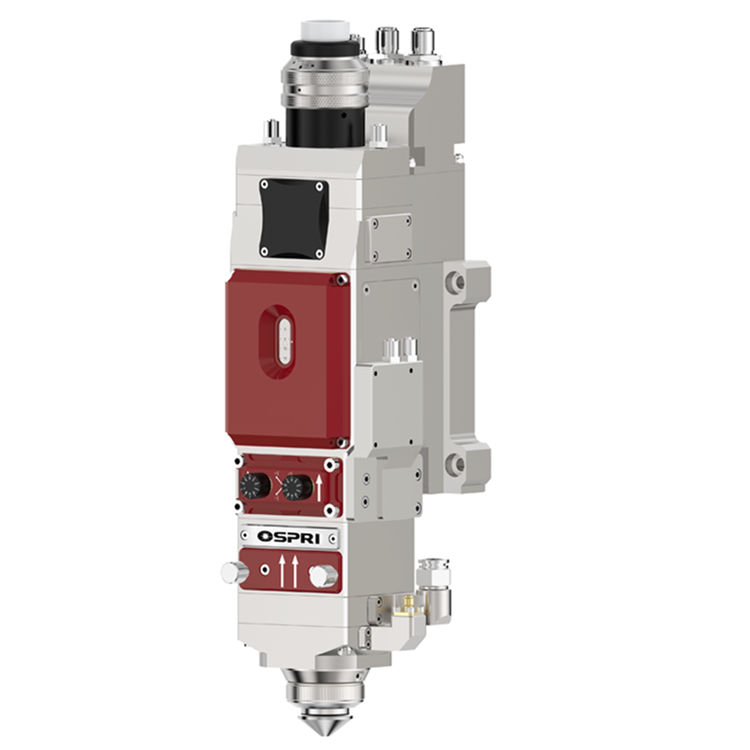

Handheld welding gun

Power on and off emergency stop button

touch screen control surface

Universal wheel with brake

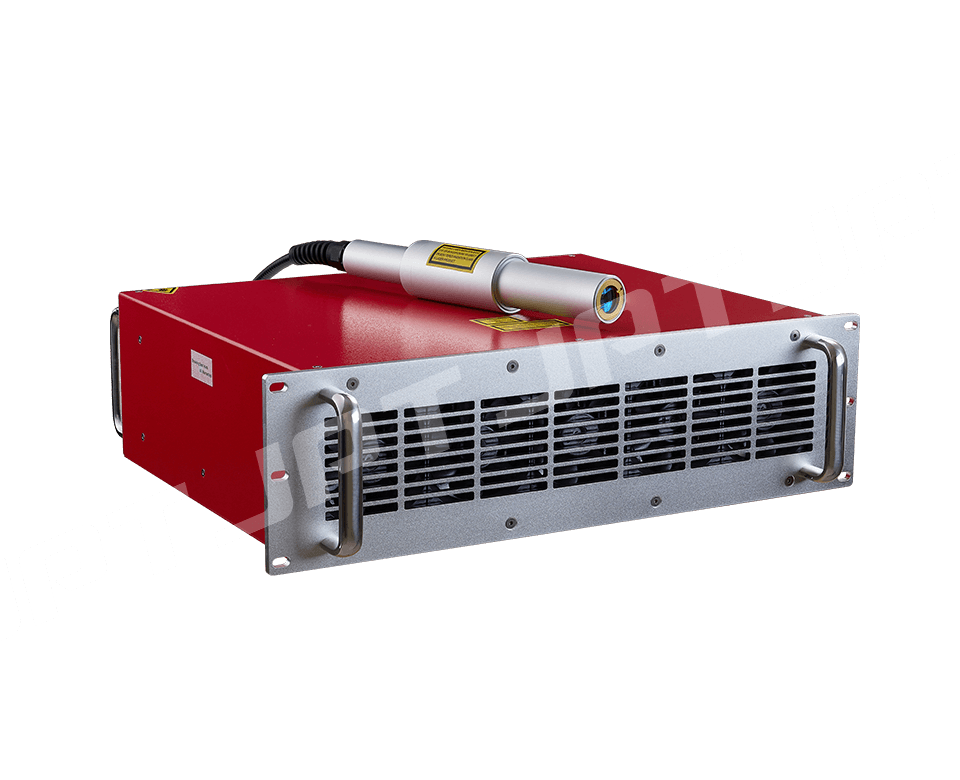

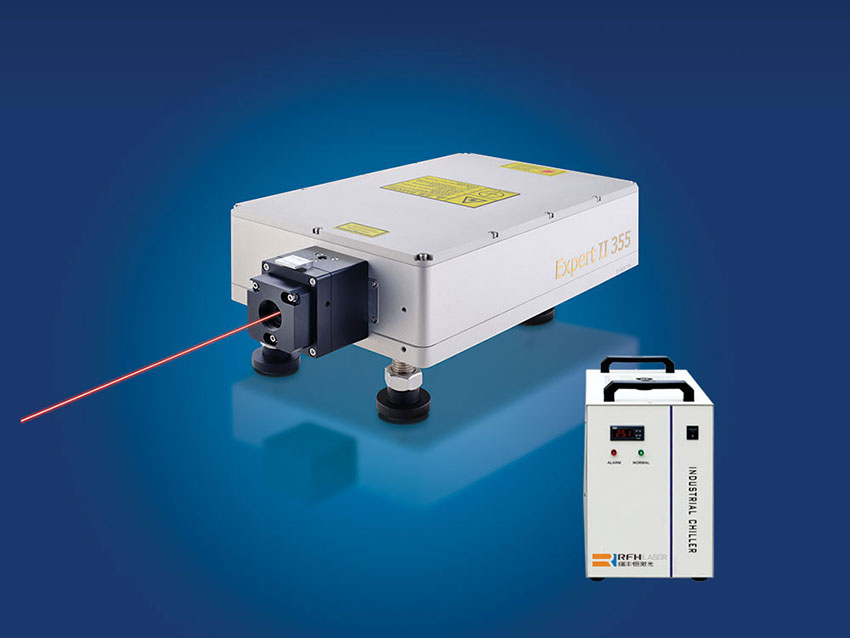

Laser (in the cabinet)

Chiller (in the cabinet)

Matching wire feeder

Welding wire in box

Equipment principle overview:

The laser light of the laser is transmitted from the optical fiber line to the hand-held laser welding gun and then focused on the surface of the welding object. After being absorbed by the carrier, it is converted into thermal energy to melt the material or the welding wire to achieve the melting effect. The high-quality weld bead is formed by auxiliary inert gas protection, so that the two The objects are firmly welded together.

(The water of the chiller flows to the laser and the hand-held welding head to cool down and maintain a constant temperature, thus protecting important components.)

Handheld welding head technical parameters:

Interface type QBH

Power range 2000W

Laser wavelength 1064-1080nm

Light spot adjustment (0.2-5) mm

Collimated focal length 50mm

Focusing focal length 120/150mm

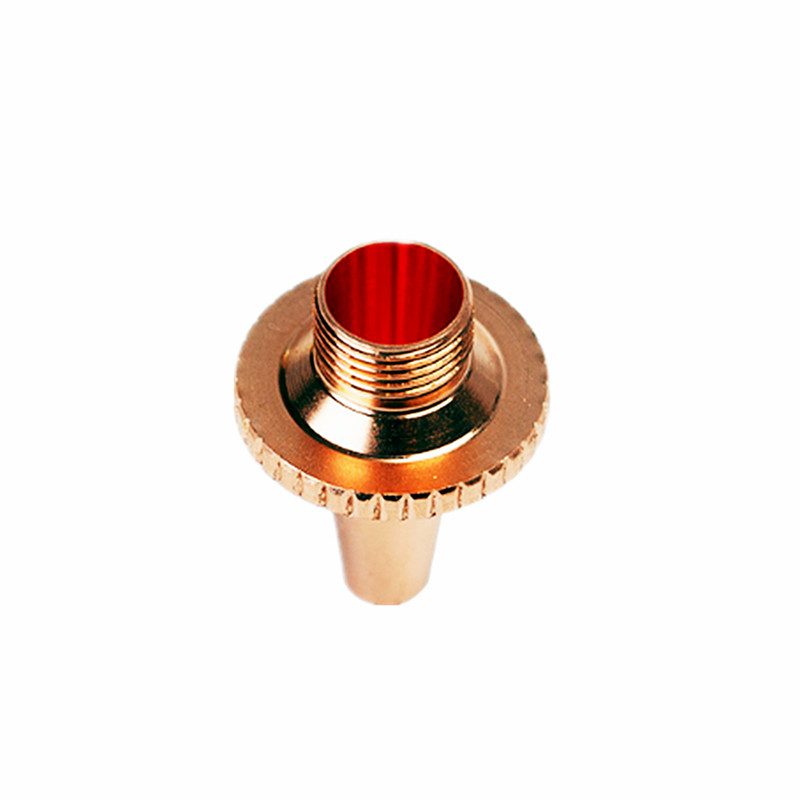

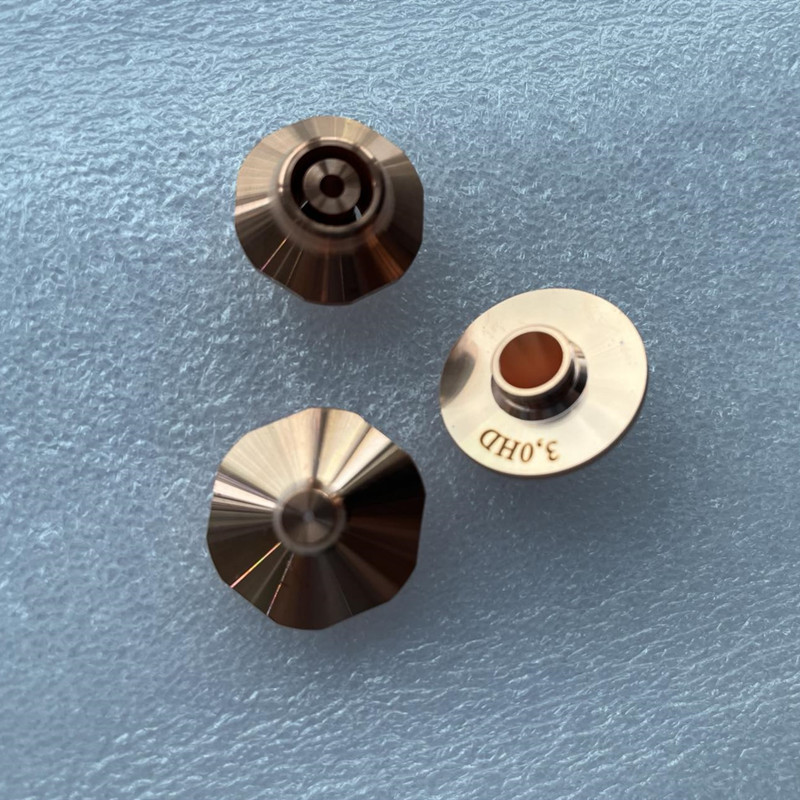

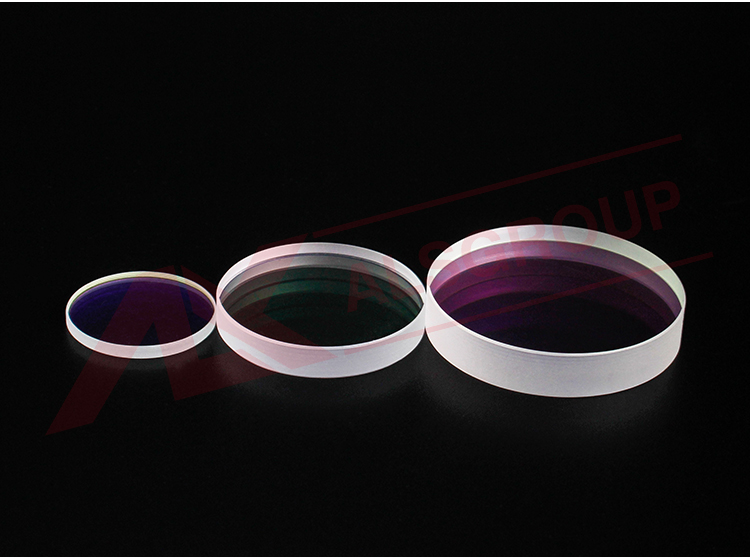

Protective lens D20X2mm

Cooling method Water cooling

Handle weight 1.2KG

Mode Selection Dot-Line-Circle-Double 0-Triangle-8 Word

Features & Applications

Fast | Performance better | | Free tretment| precision & Eco-friendly

Suitable for welding between titanium, metal, zinc, steel, copper, aluminum, chromium, niobium, metal, gold, and can also be used for welding between different metalsr 。

Applications:

Industry application and sample display

It is suitable for complex and irregular welding process industries such as kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel home furnishing, lighting and molds, advertising words and other industries. Such as various specifications of stainless steel, stainless steel color plate, iron sheet, pure iron, pure aluminum, aluminum alloy, etc., support fillet welding, vertical welding, tailor welding, stitch welding and other welding methods, the welding interface is firm, the welding seam is consistent, Neat and beautiful, not deformed.

Welding Principle:

Laser welding VS the argon arc welding:

Welding samples comparison

Laser welding technical parameters (For reference only):

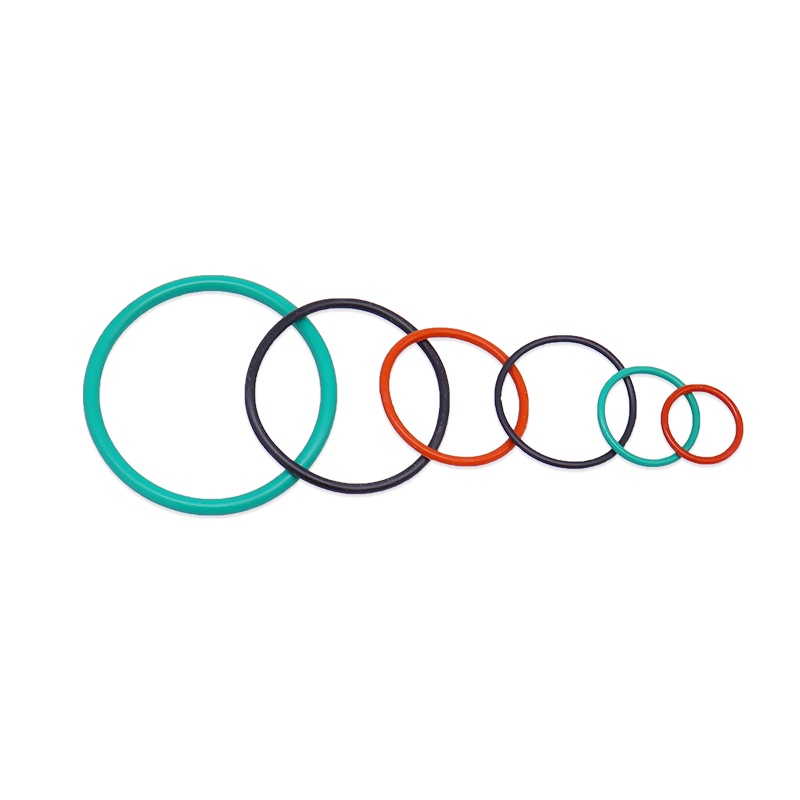

Main components technical parameters:

Note:

Usually, the welding wire is larger than the welding seam, such as the welding seam 1mm, the welding wire should be equal to or greater than 1mm

The diameter of the current welding wire is between 0.8 and 1.6, the minimum welding wire is 0.8, and the thickest is 1.6. If the welding seam exceeds 2mm and the material thickness is more than 2mm, you can try to use "surfacing", that is, repeat adding welding wire to increase the height. (Currently more than 1.6mm weld, it is recommended to confirm with the company's professional and technical personnel)

The aluminum wire is recommended to be matched with the wire of the 5 series or above (such as 5356, etc.), and the diameter of the aluminum welding wire is recommended to be more than 1.2mm.

Functional protection and features

The signal status display on the page: Shutter Gas Welding Torch Status Conduction Status Laser Head Status

1. Optical shutter: control of the optical signal of the laser switch. (In normal use, turn on the light

The light-emitting signal of the shutter button takes effect, and the shutter button will be activated after 15 minutes of no operation.

automatic shutdown)

2. Gas: For gas control, percentage control is effective when a proportional valve is installed.

3. Welding torch status: refers to the light-emitting trigger button on the torch head, and the trigger button starts

when the light is on.

4. Conduction state: refers to the loop signal generated by the gun head touching the metal plate. (Gun

When the head touches the metal plate with alligator clip, the conduction signal light is on, this signal is the light protection

protection function, short circuit is prohibited)

5. Laser head status: refers to the status of the laser gun head motor. (The motor is powered on normally

This light is on during communication, and when the motor fails and does not work, the signal light is off and the liquid crystal of the gun head

The screen displays the E signal alarm, the light signal is locked and the trigger light button is invalid)

Control section in the page: Laser Control

Laser head control

gas control

1. Laser control:

1. Power: 0-100%

2. Frequency: 50-30000HZ

3. Duty cycle: 0-100%

Suggestion: The power selects the appropriate laser power according to different material thicknesses. The frequency is established

3000-5000HZ is recommended. Duty cycle: according to the requirements of welding penetration. When the thin plate does not penetrate the welding, the duty cycle can be appropriately reduced

2. Laser head control:

1. Patterns: Point, Line, Circle, Double O, Triangle

shape, figure 8 (3 new flare modes are added, there are 6 different flare shapes in total

state selection)

2. Frequency: refers to the motor speed (2-46HZms) adjustable, among which

1HZ=10 circle calculation.

3. Width: refers to the spot size, (0.2-5mm) adjustable.

Suggestion: Dot mode: refers to the state where the motor does not swing, and the light spot is the smallest. penetrate

Strong force, can be used for penetration welding, stitch welding, or thicker materials.

Linear mode: refers to swinging a motor to connect the points into a line, which can be adjusted

The width of the direction, the energy density is concentrated, it can have a certain penetrating power to the thick plate, and the

Fillet welding is used for tailor welding.

Circular: 2 motors are oscillated, and the dots are edged into different light spot patterns, which can

Adjusting the diameter, the energy density is uniform, the advantages of thin plate welding are obvious, and the minimum

0.3mm sheet welding. It is used for tailor welding and internal fillet welding.

Double O, triangle, figure eight: two motors swing, the main function is

The hollowness of the spot is reduced, the laser dispersion range is wider, and the sheet is radiated by light.

Larger and more even

3. Gas control: Gas advance and delay are recommended to be set at about 150ms.

Used to protect welding fumes from contaminating the protective lens. Proportional valve, when connected to proportional valve

Gas Percentage control of gas availability.

Protective function

1. Laser head protection: When the laser head has (E) signal or no data output,

The system detects the motor failure, the status light of the laser head goes out, and the system stops sending at the same time

outgoing signal. The torch status can be lit, but the trigger is invalid.

2. On-state protection: The on-signal is controlled by an independent 24V voltage.

When the interference signal or non-own 24V voltage is reached, the state is off, and the system stops sending

Send out an optical signal. The torch status can be lit, but the trigger is invalid.

3. Welding torch state protection: when the welding torch receives the conduction state and the laser head state, all

When normal, the trigger button can be pressed to emit light.

4. Trigger button protection: This button sets up multiple independent circuits, that is, in any

If the protection function is disturbed or fails, releasing the trigger button can force the system to stop.

Stop the connection with the laser and effectively prevent the laser from being emitted.

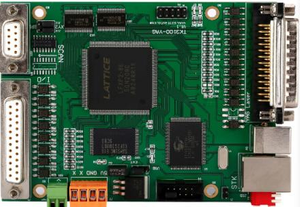

5. System leakage protection: The motherboard adds multiple isolation protections to prevent chassis leakage.

Lightning and other factors burn out the motherboard or interfere with the motherboard.

6. Shell protection: The motherboard and driver are protected by a metal shell, which can better shield the outside world

interference.

Machine inner look:

Laser Safety, Operational Safety Notices:

Please pay attention to the following when operating the installation:

1) Please use this product correctly according to the instructions for use, do not damage the power supply and do not step on, twist or pull the cable. Damaged cables can cause electric shock, short circuit, and fire.

2) Please turn off the power to stop the operation when there are abnormal phenomena such as burning smell, abnormal sound, abnormal heat, smoke, etc., otherwise there will be danger of electric shock, fire, etc.

3) Foreign objects, especially metal or conductive objects, should be avoided in the circuit to prevent short circuit or cause failure. Do not use it in a humid environment. Water in the electrical part may cause electric shock or short circuit. It is powered on.

4) Please wear protective glasses and safety gloves during laser processing. It is strictly forbidden to point the muzzle of the gun to the human body and eyes after the power is turned on and after the laser power is turned on. After the processing is terminated, the workpiece is still in a high temperature state, please wear gloves to touch the workpiece.

5) During welding, the welding parts and the console are prohibited from being connected to the ground, and the correct use is safe to contact the light. The muzzle is strictly prohibited from sight glasses and skin.

Installation and debugging:

The company is responsible for guiding the installation and commissioning of the equipment. According to the contract, after receiving the payment, the company will arrange delivery. Before delivery, the company will communicate with your company in advance to prepare for the corresponding power supply, electrical, site requirements and other preparations.

Our equipment has sturdy packaging suitable for long-distance transportation and multiple handling, loading and unloading, so as to avoid damage to the boxes during transportation, and we have protective measures such as moisture-proof, mildew-proof and rust-proof according to the characteristics of the equipment to ensure that the equipment is not damaged. In case of safe arrival location.

6.2 Main installation environment

Workshop temperature: 5-38 ℃, when it is lower than 5 ℃, add antifreeze and turn on the laser when the temperature reaches 15 ℃ or more after starting the chiller

Humidity: 30%-85% without condensation

Three no: no dust, no oil fume, no corrosive gas, need to use isolation voltage stabilizer and good grounding

6.3 Pre-sale, in-sale and after-sale service

(1) Pre-sales service

Before signing the contract, the company can provide customers with product samples and technical and price consultation and answers free of charge.

(2) On-sale service

If there are any technical problems during the installation of the product, you can contact the local regional manager or after-sales technicians at any time. If you need on-site technical support, you can communicate with the local sales manager and arrange for the company to coordinate.

(3) After-sales service

Customer service response time is within 24 hours within the warranty coverage of the contract term,