Laser Marking Laser Engraving Laser Cutting Laser Cutting Welding Industrial dust and smoke collection system

Product description:

Hazards of laser soot:

The harmful smoke and dust generated during laser marking, engraving, cutting and welding are very harmful to human health and the core components of the machine. The smoke and dust diffuses in the machine for a long time, which will damage the laser cutting head and servo motor. If it is discharged into the air, if it is inhaled for a long time, it is easy to cause various respiratory poisoning and occupational diseases. If you do not deal with these harmful waste gas or do not deal with it thoroughly, it will not only cause employees to be dissatisfied and leave, but also will be complained and punished by surrounding neighbors and environmental protection departments. Therefore, it is urgent to choose a waste gas treatment method.

Approach:

1. Direct external discharge: install high-power exhaust fans and pipelines to discharge to the outdoors (some discharge from high altitude or sewage). Disadvantages: It cannot be moved at will, the high-power exhaust fan required for complex pipelines consumes a lot of electricity, and the effect of reducing odors in high exhaust and sewers is very small, and a strong odor will also be generated within a certain distance around.

2. Water discharge: install a spray tower outside the workshop, and the waste gas is discharged to the outdoors after being sprayed with water. This effect is not much better than high discharge and sewer discharge, the purification rate is generally below 40%, and the cost is high.

3. Soot purifier: Soot enters the filter system inside the equipment through the smoke pipe and is discharged on the spot. The filter system is composed of physical and chemical multi-level filter systems, and the purification rate is as high as 99%, which not only removes smoke but also eliminates pungent odors. Low power consumption, no external discharge, no installation, and can be moved with the processing location. This type of equipment is specially used for the purification of smoke and dust such as laser machines.

◇ Integrated industrial design of the fuselage, the appearance is simple and elegant, stable and elegant. Using metal frame structure, high-quality cold-rolled steel plate electrostatic spray process, durable

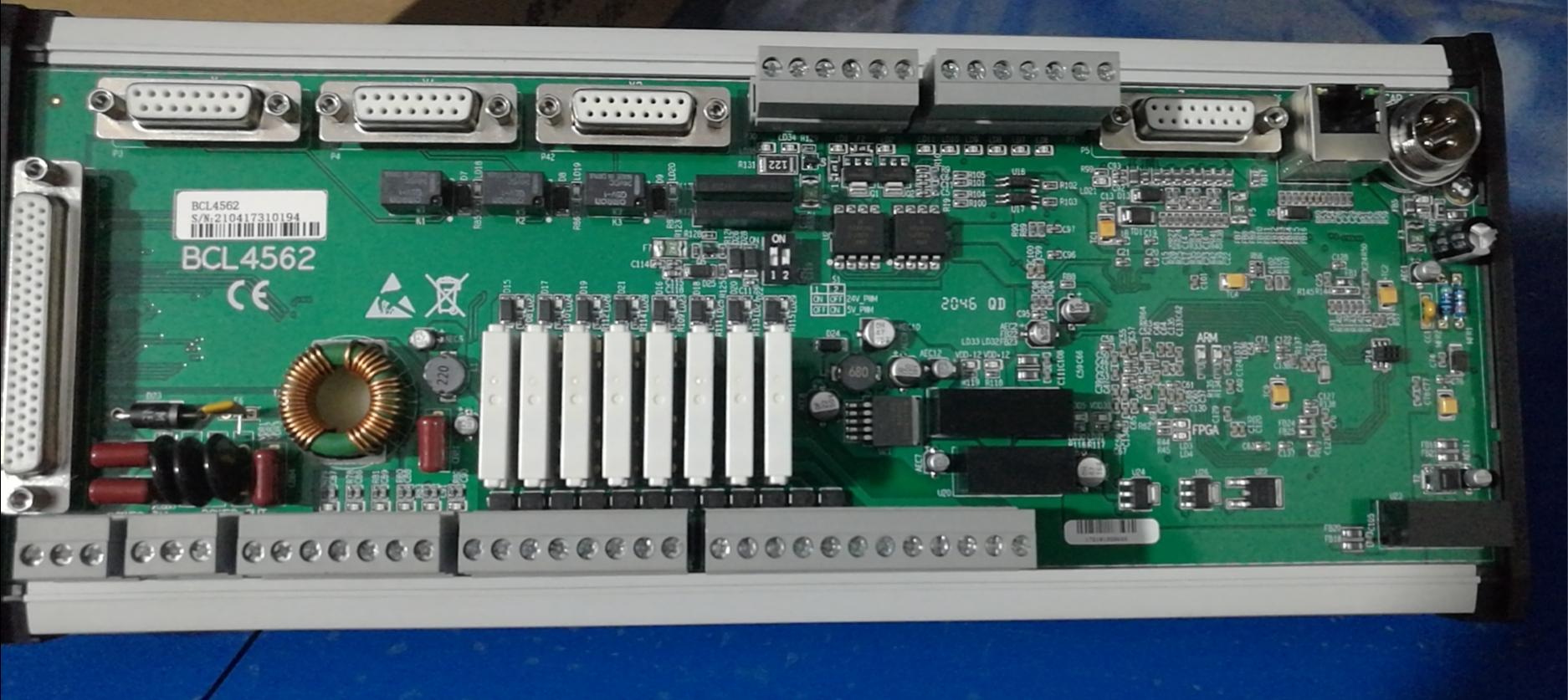

◇ Self-developed control system, humanized operation panel is more classic and delicate, full of scientific and technological content.

◇ The air inlet flange can be flexibly prepared according to the demand.

◇ The filter element adopts American HV filter element, quick-release design, efficient and convenient to install.

◇ Adopt Siemens/Bide high-efficiency and high-speed motor, built-in controller form, performance and quality are more guaranteed.

◇ Stable operation, low noise, high efficiency, low energy consumption, long working hours. No need for regular maintenance and lower cost.

◇ The wind wheel adopts eddy current design and special alloy material, which can effectively prevent the wind wheel from being corroded. The unique dynamic balance correction technology makes the rotor run more smoothly and reliably.

◇ High negative pressure, high suction, higher filtration rate.

◇ Adopt multiple filtering design. Filter layer by layer to ensure that harmful smoke and dust are filtered out more thoroughly. The purification rate can reach up to 99.9%.

◇ Modular design, automatic back blowing and dust removal at regular intervals, longer filter life and lower replacement cost.

◇ Independent research and development control system: support EtherCAT bus protocol, energy-saving frequency conversion control.

Configuration description:

| Model | TODC-4L/6L/6LS/8L |

| Controller | Independent R&D |

| HMI | 4.3’Touch screen |

| Motor | SIEMENS |

| Backflush valve | Pulse control |

| Filter | HV Made in USA/CHINA |

| Protocol | EtherCAT |

| Energy saving(optional) | Inverter control |

1. Smoke air intake

2. Filter element

3. Ash Bucket

4. Clean air outlet

5. Gas tank

6. Electromagnetic pulse valve

7. Flower board

8. Pulse back blowing compressed air

9. Dust falling

| Model | TODC-4L | TODC-6L | TODC-6LS | TODC-8L |

Filter cartridge

material | HV/Ahlstrom/TORAY F9 HV/Ahlstrom/TORAY,F9 | HV/Ahlstrom/TORAY F9 HV/Ahlstrom/TORAY,F9 | HV/Ahlstrom/TORAY F9 HV/Ahlstrom/TORAY,F9 | HV/Ahlstrom/TORAY F9 HV/Ahlstrom/TORAY,F9 |

Number of Filter

cartridge | 4 | 6 | 6 | 8 |

| Air volume | 3200m3/h | 4000m3/h | 6000m3/h | 7000m3/h |

| Air pressure | 3000 | 3600 | 4500 | 5000 |

Filtration

efficiency | 99.99% | 99.99% | 99.99% | 99.99% |

| Filtering area | 82M2 | 120M2 | 120M2 | 166M2 |

| Entrifugal fan | 5.5KW SIEMENS | 7.5KW SIEMENS | 11KW SIEMENS | 11KW SIEMENS |

| Collector capacity | 45L | 50L | 50L | 90L |

| Power requirments | THREE-PHASE FIVE-WIRE, 380V | THREE-PHASE FIVE-WIRE, 380V | THREE-PHASE FIVE-WIRE, 380V | THREE-PHASE FIVE-WIRE, 380V |

Air pressure

request | 0.6MP, compressed air

without oil and water | 0.6MP, compressed air

without oil and water | 0.6MP, compressed air

without oil and water | 0.6MP, compressed air

without oil and water |

| Unit weight | 700KG | 900KG | 940KG | 1200KG |

Outline

Dimension(mm) | A:2198,B:1348, C:1060,D:303 | A:2807,B:1423, C:1180,D:383 | A:2987,B:1498, C:1180,D:383 | A:2575,B:2215, C:1016,D:453 |

Common spare parts:

1. Filter assembly - for Topsinn

2. Diaphragm valve with solenoid valve

3. Cartridge cover

4. Service Door Gasket

5. Dingxin intelligent environmental protection control board TODC-D1

6. TODC HMI